Introduction

In the landscape of synthetic elastomers, Nitrile Butadiene Rubber (NBR) has carved a crucial role thanks to its outstanding resistance to oil, fuel, and chemicals. Often regarded as a workhorse material for industries ranging from automotive to healthcare, NBR’s durability, flexibility, and affordability have made it an indispensable polymer in modern manufacturing. As industries continue to evolve with changing regulations, sustainability goals, and product innovation, the Nitrile Butadiene Rubber (NBR) market is adapting, expanding, and gaining momentum.

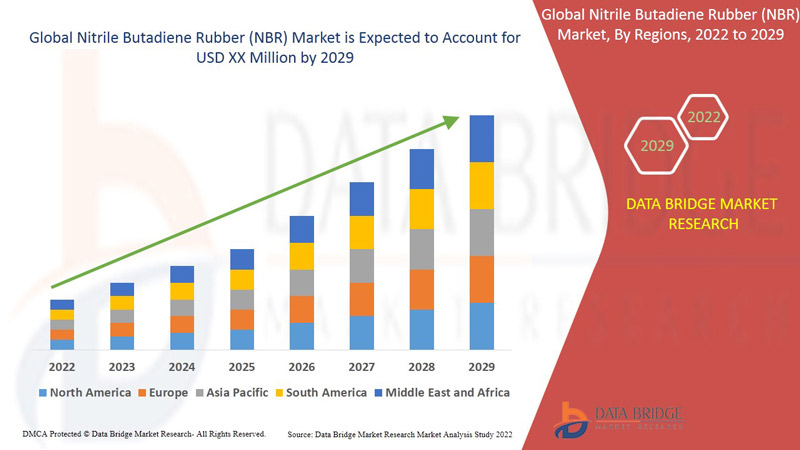

Source : https://www.databridgemarketresearch.com/reports/global-nitrile-butadiene-rubber-nbr-market

What is Nitrile Butadiene Rubber?

NBR is a synthetic rubber derived from acrylonitrile and butadiene. It is known for its exceptional resistance to petroleum-based oils and fuels, making it ideal for seals, gaskets, hoses, and gloves. Its mechanical strength, temperature tolerance, and low compression set make it highly versatile for both industrial and consumer applications.

NBR can be found in:

-

Automotive fuel hoses and transmission belts

-

Industrial seals and O-rings

-

Disposable gloves (particularly in healthcare and labs)

-

Footwear, adhesives, and foam applications

Market Drivers

1. Automotive Industry Growth

The automotive sector remains one of the largest consumers of NBR. With the rising demand for vehicles—especially in developing countries—NBR components like fuel hoses, grommets, and seals continue to see consistent demand. As electric vehicles grow in popularity, NBR formulations are also being adapted for new fluid systems and thermal management components.

2. Healthcare and PPE Demand

NBR gloves have seen a surge in demand, especially during and after the COVID-19 pandemic. Their chemical resistance and durability make them a preferred choice over latex in many medical, laboratory, and industrial settings. As infection control remains a global health priority, this segment continues to expand.

3. Industrial and Oil & Gas Applications

NBR’s resistance to chemicals and oils makes it vital in the oil & gas, mining, and manufacturing sectors. It’s widely used in the production of hoses, packers, seals, and gaskets in high-pressure and high-temperature environments.

4. Preference Over Natural Rubber

Due to increasing latex allergies and the volatile pricing of natural rubber, manufacturers are turning to NBR as a cost-effective and safer alternative, especially for gloves and other contact products.

5. Asia-Pacific Manufacturing Boom

Rapid industrialization in countries like China, India, and Vietnam is driving up demand for NBR products. As these economies expand their automotive, healthcare, and construction sectors, NBR consumption continues to rise.

Regional Overview

-

Asia-Pacific dominates the NBR market, accounting for the largest production and consumption volumes. Cost-effective manufacturing and growing end-use industries contribute significantly to regional growth.

-

North America shows strong demand in automotive, aerospace, and healthcare sectors, with a focus on high-performance and regulatory-compliant NBR materials.

-

Europe maintains a steady market due to its mature automotive sector and stringent quality standards for industrial and medical applications.

-

Latin America, Middle East & Africa are emerging markets with growing industrial and infrastructure development, creating new opportunities for NBR applications.

Challenges in the NBR Market

Despite its widespread utility, the NBR market faces certain challenges:

-

Raw Material Price Volatility: NBR is petroleum-based, making it sensitive to crude oil price fluctuations.

-

Environmental Concerns: As a non-biodegradable synthetic polymer, there is rising pressure to develop more sustainable alternatives or improved recycling methods.

-

Competition from Alternatives: Thermoplastic elastomers (TPEs) and newer synthetic rubbers are being explored as lighter, more customizable materials.

-

Regulatory Compliance: Stringent environmental and health regulations, especially in Europe and North America, are influencing production practices and material formulations.

Technological and Market Trends

To stay competitive, players in the NBR market are focusing on:

-

Bio-based NBR Development: Efforts are underway to derive NBR-like polymers from renewable sources to reduce reliance on fossil fuels.

-

Advanced Blends and Composites: Blending NBR with PVC or other polymers to enhance strength, flame resistance, and weatherability.

-

3D Printing Applications: Emerging interest in using NBR-based materials in additive manufacturing for flexible, oil-resistant components.

-

Customized Grades: Tailored NBR formulations for specific end-user needs such as low-temperature performance, enhanced tensile strength, or color customization.

Competitive Landscape

The global NBR market features a mix of multinational chemical corporations and regional manufacturers. Key strategies include:

-

Expanding production capacity in high-growth regions

-

Investing in sustainable and specialty-grade NBR compounds

-

Strategic partnerships with automotive and healthcare companies

-

Enhancing supply chain resilience for raw materials

Future Outlook

The future of the NBR market looks promising, with a strong base of existing applications and new areas of growth. Demand for protective equipment, automotive components, and industrial seals will continue to support stable growth. However, innovation will be key to addressing environmental concerns and keeping pace with evolving end-user requirements.

The market is expected to benefit from:

-

Technological upgrades in NBR formulation

-

Diversification into eco-friendly and recyclable variants

-

Continued expansion of the global automotive and healthcare sectors

-

Regional diversification in both production and consumption

Conclusion

Nitrile Butadiene Rubber may not always be in the spotlight, but its role in enabling industrial resilience, healthcare safety, and automotive efficiency cannot be overstated. As industries modernize and global demand diversifies, NBR will continue to be a material of choice—adaptable, durable, and essential. The path forward for the NBR market is one of steady innovation, responsive manufacturing, and alignment with global sustainability trends.

- Data Bridge Market Research analyses the nitrile butadiene rubber (NBR) market will exhibit a CAGR of 7.68% for the forecast period of 2022-2029.

- Data Bridge Market Research analyses the nitrile butadiene rubber (NBR) market will exhibit a CAGR of 7.68% for the forecast period of 2022-2029.

- nitrile butadiene rubber (NBR) market, nitrile butadiene rubber (NBR) market scope, nitrile butadiene rubber (NBR) market size

Related posts:

Top Carrier Oil Suppliers in India for Bulk & Wholesale Buyers

Top Carrier Oil Suppliers in India for Bulk & Wholesale Buyers

Atlas Pro ONTV : La Révolution de la Télévision par Internet

Atlas Pro ONTV : La Révolution de la Télévision par Internet

Luxury or Budget? Finding the Right Heathrow Transfer for You

Luxury or Budget? Finding the Right Heathrow Transfer for You

What Is Cold Rolled Stainless Steel Coil and Why Does It Matter?

What Is Cold Rolled Stainless Steel Coil and Why Does It Matter?

Make Impact with Commercial Signs Raleigh NC: A Strategic Guide to Business Success

Make Impact with Commercial Signs Raleigh NC: A Strategic Guide to Business Success

PEX vs Copper in New Homes: What’s Right for You? | Creative Repipe

PEX vs Copper in New Homes: What’s Right for You? | Creative Repipe

Top Benefits of Professional Roller Shutter Repair in London

Top Benefits of Professional Roller Shutter Repair in London

What to Expect When Buying a Solar Battery Locally – Pricing, Quality, and Local Support Insights

What to Expect When Buying a Solar Battery Locally – Pricing, Quality, and Local Support Insights