Parchment paper: a common and convenient material that is found in cooking, baking, crafts, and packaging. It is sold more than others, either to experts or amateurs, because it has unique properties like resistance to high temperatures and a lack of stickiness. Nevertheless, have you ever pondered how this simple sheet of paper is prepared, especially when it is personalized in order to satisfy the unique needs? Raw materials and finished item procedures are a delicate combination of science and art. The production of parchment paper entails a series of activities that are discussed in this article to illustrate how the manufacturers handle the simple materials that they are supplied with to come up with a product that is exclusive and very marketable to satisfy diverse needs.

Harvesting and Treatment of Wild Outputs

Parchment paper manufacturing begins with the selection of raw material: the cellulose fiber is the most crucial component here, and it is either extracted with the help of wood pulp or out of the cotton linters. It is with the assistance of these fibers that all the paper products (not excluding custom parchment paper as well) are made. It is also a factor of the raw materials used, which establishes the durability and the feel of the end sheet. The fibers that are collected are cleaned and refined after harvesting to get rid of the impurities and prepare them. This plays a significant role in concluding that the parchment paper would be firm, elastic, and tough enough to endure heat and humidity when put in use.

Making of the Paper Stock

The raw material is cooked, and this is transformed into pulp. Pulping is whereby the cellulose fibers are broken down in a combination of slippery substances under the equipment of mechanical methods or chemicals. In mechanical pulping, the fibers are physically ground and, in chemical pulping, there is solubility of lignin and other impurities by the use of chemicals, thus producing a chemical-like pulp. The process is critical because it forms the paper textured and smooth. Washing and bleaching of the pulp is then done according to the required tint and finish. At this stage, manufacturers get a chance to begin modifying the pulp to accommodate a specific need, and this will be the source of custom parchment paper.

Preparation of the Parchment or Sheet

The pulp is then transferred to a paper machine, where the pulp is in the process of being thinned out as it passes through the chamber and into a moving mesh screen. This is so that the water can be drained, u living behind a thin wet fibre sheet that is thin. This is then pressed on the sheet, and the hot rollers are designed to shed the water. But like parchment paper, an additional treatment is performed with parchment paper to improve its non-sticking quality and to make it more heat resistant. This usually involves a treatment inside a coating bath or impregnation with substances like sulphuric acid or other chemicals that have the potential of changing fiber structure so they become stronger and develop resimoisture resistancee The resulting product is a quasi-transparent, smooth, watermark-free, free, and durable parchment sheet that may be further processed.

Personalisation and Output of Special Requirements

The manufacturers know that the industries and customers face unique requirements for using special parchment paper. The parchment papers are printed and customized to meet the needs. We employ food-safe inks and leading technologies in order to add some logos, patterns, or branding details to custom-printed parchment paper. The techniques ensure that there is are color and clear design that is not affected by heating. To brand a bakery, package gourmet food, and use parchment paper to customize unique gift items has been applied. Besides making the businesses stand out, customization has ad to the parchment paper.

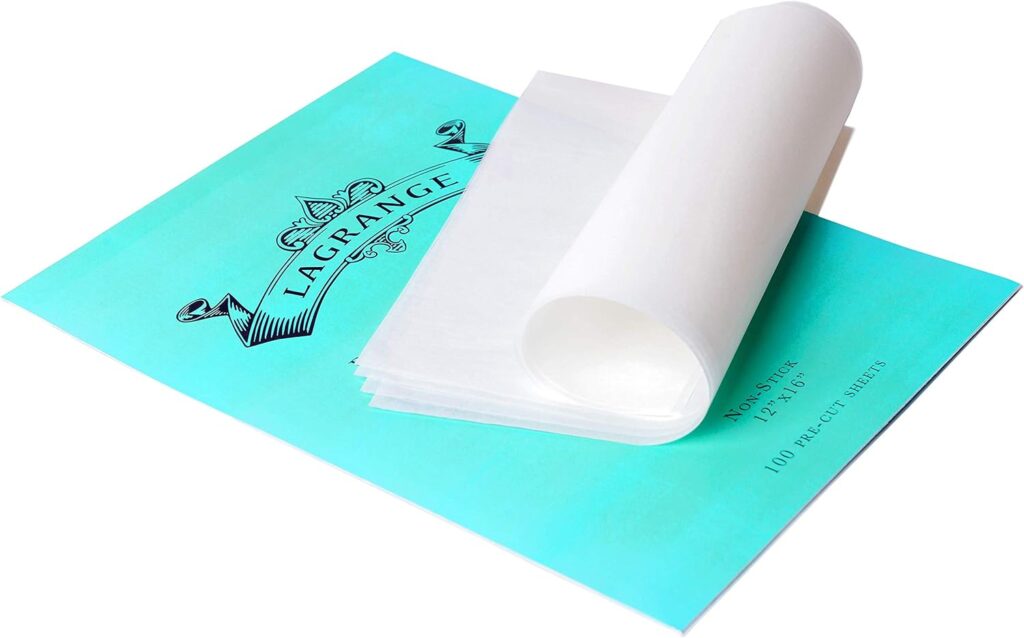

Cutting and Size of the Sheets

The parchment paper is printed on and treated, and cut to a certain size so that it may be used in several areas. This phase plays a critical role in offering the customer specific parchment paper sheets based on their needs. Everything is cut precisely, whether it is the commercial bakery rolls or the home baking sheet one, although they are produced in large rolls or small she,ets respectively. The sheets are also packaged in convenient formats, and this increases user experience. This adjustive measure in size is what contributes to making the parchment paper flexible and capable of fitting various cooking and crafting.

Quality And Seal Verification Quality And Seal Verification

To ensure maximum quality, each lot of the parchment paper is strictly checked in terms of quality control. The tests involve heat resistance, durability, moisture repellency, and print integrity. Also, parchment paper is exposed to food in many cases, is expected to be ve,ry safe, and sometimes lies directly on food, so it must be very safe and it must not contain any bad chemicals or contaminations. The extensive inspection process guarantees confidence to the customers in the sense that custom personalized parchment paper would be safe, reliable, and would consistently deliver in their particular applications.

Distribution and Packaging

Quality checks are done, after which the parchment paper is packaged, ready to be shipped without spoiling its condition. The role of customization in packaging allies in the elaboration of many companies by using branded boxes, as well as using friendly elements. After packaging, the parchment paper is then distributed to businesses and consumers through the use of wholesalers or retailers. Manufacturing of the parchment paper in a customized manner and in a highly productive way is one of the ways of satisfying various market demands in a shorter time, and hence, buyers can obtain the best products that suit their businesses or their individual uses.

Conclusion

The stages of the creation of custom parchment paper out of materials are an interesting mixture of natural resources refinement, high-quality chemical processing, and accurate production. Starting with the selection of appropriate cellulose fibers to cutting, printing, ing, and finishing, all these stages are well-regulated to provide a product that satisfies certain customer demands. Customization of parchment paper sheets and printing exclusive designs has changed this classic material into a me versatbecomend modern solution to many industries. Be it kitchens, packaging, or crafts, the end parchment paper shows considerable handwork of innovation that ensures that the end product is good to use each time. This is how science and creativity meet in the common products, this route of raw materials to the finished parchment paper.

- How Is custom Parchment Paper Made from Raw Materials?

- Discover the fascinating process behind making high-quality parchment paper, from raw materials to finished sheets designed for various uses.

- custom Parchment Paper

Related posts:

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Fitness for Mental Clarity: Unlock Your Focus and Inner Strength with DG FIT MIND

Fitness for Mental Clarity: Unlock Your Focus and Inner Strength with DG FIT MIND

Top Carrier Oil Suppliers in India for Bulk & Wholesale Buyers

Top Carrier Oil Suppliers in India for Bulk & Wholesale Buyers

Atlas Pro ONTV : La Révolution de la Télévision par Internet

Atlas Pro ONTV : La Révolution de la Télévision par Internet

Luxury or Budget? Finding the Right Heathrow Transfer for You

Luxury or Budget? Finding the Right Heathrow Transfer for You

What Is Cold Rolled Stainless Steel Coil and Why Does It Matter?

What Is Cold Rolled Stainless Steel Coil and Why Does It Matter?

Make Impact with Commercial Signs Raleigh NC: A Strategic Guide to Business Success

Make Impact with Commercial Signs Raleigh NC: A Strategic Guide to Business Success

Essentials Hoodie Design Philosophy: Minimalism Meets Statement

Essentials Hoodie Design Philosophy: Minimalism Meets Statement