In highly corrosive environments, choosing the right material for flanges is critical. One of the top-performing materials in such conditions is Flange 254 SMO, a super-austenitic stainless steel known for its excellent corrosion resistance, especially in seawater, chloride-rich, and acidic environments. In this blog, we will explore everything you need to know about Flange 254 SMO — its composition, properties, advantages, and applications in demanding industrial sectors.

What is Flange 254 SMO?

254 SMO, also known as UNS S31254, is a high-alloy austenitic stainless steel developed for extreme resistance to chloride stress corrosion cracking, pitting, and crevice corrosion. Flanges made from this alloy are known as Flange 254 SMO and are widely used in marine, chemical processing, and offshore applications where standard stainless steel grades fail.

This steel has a high content of molybdenum (6%), chromium (20%), and nitrogen (0.2%), contributing to its exceptional strength and corrosion resistance. Flange 254 SMO offers both durability and cost-efficiency by reducing maintenance and replacement needs in harsh environments.

Key Properties of Flange 254 SMO

-

Superior Corrosion Resistance

254 SMO flanges have excellent resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking, which is particularly beneficial in seawater and brackish water environments. -

High Strength

The material is almost twice as strong as 300-series stainless steels. This makes it suitable for high-pressure systems without increasing material thickness. -

Excellent Weldability

Despite its high alloy content, 254 SMO can be welded using standard techniques without the risk of hot cracking or loss of corrosion resistance. -

High Ductility and Toughness

The alloy retains ductility and impact strength even at low temperatures, making it ideal for cryogenic applications. -

Oxidation Resistance

254 SMO performs well in high-temperature oxidation conditions, ensuring longer service life in heat-exposed applications.

Chemical Composition of 254 SMO (UNS S31254)

| Element | Content (%) |

|---|---|

| Chromium | 19.5–20.5 |

| Nickel | 17.5–18.5 |

| Molybdenum | 6.0–6.5 |

| Nitrogen | 0.18–0.22 |

| Copper | 0.5–1.0 |

| Carbon | ≤ 0.02 |

| Iron | Balance |

This unique blend allows 254 SMO to outperform other grades like 316L and 904L in corrosive environments.

Types of Flange 254 SMO

Flanges are available in various designs to suit different piping needs. Some of the common types include:

-

Weld Neck Flanges

-

Slip-On Flanges

-

Socket Weld Flanges

-

Blind Flanges

-

Lap Joint Flanges

-

Threaded Flanges

All these types are manufactured using 254 SMO to ensure optimal corrosion resistance and mechanical performance.

Applications of Flange 254 SMO

Thanks to its outstanding corrosion resistance and high strength, Flange 254 SMO finds applications in a wide range of industries:

1. Offshore and Marine Industry

The offshore oil and gas industry relies heavily on 254 SMO for underwater pipelines and flanges exposed to salty, corrosive seawater. These flanges resist pitting and ensure leak-proof performance in extreme marine environments.

2. Chemical Processing Plants

In chemical industries where equipment is exposed to strong acids (sulfuric, hydrochloric), Flange 254 SMO ensures long-term reliability and reduces the frequency of replacements.

3. Pulp and Paper Industry

These flanges are used in bleach plants and chemical recovery systems where standard steel grades corrode quickly due to acidic and chlorinated chemicals.

4. Desalination Plants

254 SMO flanges are ideal for desalination systems where brine and high chloride levels present severe corrosion risks.

5. Power Generation

Used in condensers and cooling water systems, 254 SMO helps maintain integrity and safety in thermal and nuclear power plants.

6. Food Processing Units

In environments requiring both corrosion resistance and hygiene, such as dairy and meat processing units, these flanges are used in piping systems that deal with cleaning agents and salt-rich content.

Benefits of Using Flange 254 SMO

-

Lower Maintenance Costs: Due to its corrosion resistance, frequent replacements are minimized.

-

Extended Service Life: Flanges last longer even in aggressive environments, reducing operational downtime.

-

Versatile Applications: Suitable for both high-pressure and high-temperature applications.

-

Environmentally Friendly: 254 SMO is fully recyclable and meets many sustainable development goals.

-

Compliance with International Standards: 254 SMO flanges are manufactured as per ASTM, ASME, ANSI, DIN, and EN standards.

Challenges & Considerations

Although Flange 254 SMO offers several advantages, it is more expensive than standard stainless steels like 304 or 316. Also, due to its high alloy content, machining and forming require specialized tools and expertise.

However, the long-term savings on maintenance, repairs, and replacements make it a highly cost-effective choice for critical environments.

Conclusion

Flange 254 SMO is a powerhouse when it comes to durability, corrosion resistance, and strength. Whether it’s the marine industry or aggressive chemical environments, this flange material consistently delivers superior performance. Choosing 254 SMO flanges may have a higher upfront cost, but the long-term benefits in safety, durability, and operational efficiency make them a wise investment.

If your application demands resilience in extreme environments, Flange 254 SMO is undoubtedly the smart and sustainable choice.

- Flange 254 SMO – Properties, Benefits & Industrial Uses

- Explore the properties, advantages, and applications of Flange 254 SMO. Learn why this high-performance alloy is ideal for offshore, chemical, and marine industries.

- Flange 254 SMO

Related posts:

Discover the Best Fence Installation Services in Omaha with Huskins Services LLC

Discover the Best Fence Installation Services in Omaha with Huskins Services LLC

Summer Solstice Party Ideas & Activities for a Magical Celebration | BizzCrave

Summer Solstice Party Ideas & Activities for a Magical Celebration | BizzCrave

At the Time of Booking: What to Keep in Mind During a Medical Emergency

At the Time of Booking: What to Keep in Mind During a Medical Emergency

Streamline Your Business with an Automated Employee Payroll System

Streamline Your Business with an Automated Employee Payroll System

What to Expect When Buying a Solar Battery Locally – Pricing, Quality, and Local Support Insights

What to Expect When Buying a Solar Battery Locally – Pricing, Quality, and Local Support Insights

When Best Stock Market Institute Delhi Becomes Your Turning Point Forever

When Best Stock Market Institute Delhi Becomes Your Turning Point Forever

Learn Advanced Derivatives Trading Course from ICFM and Build Expertise in Financial Market Strategies

Learn Advanced Derivatives Trading Course from ICFM and Build Expertise in Financial Market Strategies

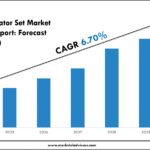

Chile Generator Set Market Trends & Forecast: Outlook to 2030

Chile Generator Set Market Trends & Forecast: Outlook to 2030