Understanding Slat Conveyors and Their Importance

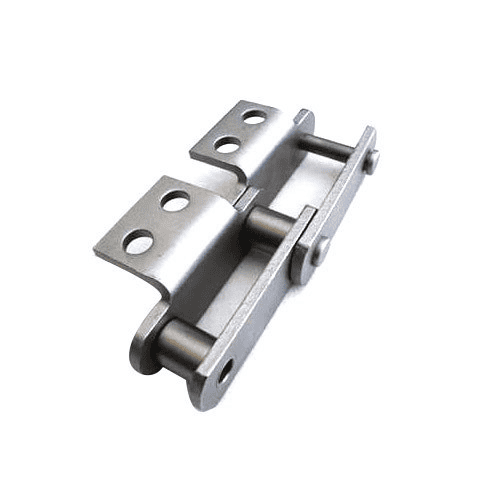

Slat conveyors are one of the most reliable and rugged types of conveyor systems used in various industrial applications. These systems are designed with durable slats or plates made from steel, plastic, or other materials that are mounted on roller chains. These slats form a continuous surface that moves materials from one point to another with precision and efficiency.

Slat conveyors are best known for their ability to carry heavy, sharp, or hot materials, making them the ideal choice for heavy-duty applications in automotive, manufacturing, food processing, and packaging industries. Their versatility and strength are what make them a preferred solution for complex material handling tasks.

The functionality of slat conveyors goes beyond simple transport. These systems can be customized with indexing, accumulation, and elevation features to suit the specific needs of an industry. From conveying engine blocks in an assembly line to transporting glass bottles in a bottling plant, slat conveyors are engineered for performance and productivity.

Why Leading Industries Trust Slat Conveyor Manufacturers

Selecting the right slat conveyor manufacturers is crucial to ensuring operational efficiency and safety. Manufacturers with deep technical expertise and industry experience bring a high level of quality control, material precision, and design flexibility. These qualities are essential for industries that demand long-lasting and maintenance-friendly solutions.

Trusted slat conveyor manufacturers invest in the latest manufacturing technologies and quality assurance processes. They provide end-to-end services including design, customization, installation, and after-sales support. This commitment to quality is what helps industries reduce downtime, save costs, and increase productivity.

Additionally, slat conveyor manufacturers understand the regulatory standards across sectors such as pharmaceuticals, food and beverage, and chemical manufacturing. Their ability to provide hygienic, easy-to-clean, and corrosion-resistant conveyor systems ensures compliance while maintaining high operational standards.

Benefits of Working with Established Slat Conveyor Manufacturers

-

Custom Design and Engineering: Professional manufacturers assess the client’s process requirements and design slat conveyors that fit the workflow seamlessly.

-

Durability and Load Handling: Slats are made from heavy-duty materials capable of handling extremely high loads and abrasive materials.

-

Smooth and Consistent Transport: Slat conveyors provide a stable and consistent conveying surface, minimizing product damage.

-

Ease of Maintenance: With simple chain-driven mechanisms, these conveyors are easy to maintain and troubleshoot.

-

Compatibility with Automation Systems: Advanced manufacturers provide conveyors that can integrate with automated systems, including robotic arms and programmable logic controllers (PLCs).

Role of Slat Conveyor Manufacturers in India’s Industrial Growth

India’s industrial sector is experiencing rapid transformation, and material handling plays a vital role in this growth. As industries shift toward automation and efficiency, the demand for high-quality conveyor systems has surged. This is where slat conveyor manufacturers in India are making a remarkable impact.

Indian manufacturers have evolved by embracing cutting-edge technologies, global manufacturing practices, and quality standards. Whether it is heavy engineering or pharmaceutical production, slat conveyors made in India are now considered reliable and cost-effective globally.

The “Make in India” initiative has also propelled the growth of local manufacturers, helping them to compete with international brands. With a strong domestic supply chain, competitive pricing, and skilled labor, slat conveyor manufacturers in India are now exporting their systems to markets across Asia, Europe, and the Middle East.

Key Contributions by Indian Slat Conveyor Manufacturers

-

Support for Small and Medium Enterprises (SMEs): By offering affordable and scalable conveyor systems, Indian manufacturers empower SMEs to improve their operations.

-

Boosting Export Potential: With rising global demand, Indian manufacturers are establishing their presence in international markets through quality and service.

-

Innovation and R&D: Top manufacturers invest heavily in R&D to develop modular and smart conveyor systems that meet evolving industry needs.

-

Job Creation and Skill Development: The growing conveyor manufacturing sector contributes to employment and the development of technical skills in the Indian workforce.

How to Choose the Right Slat Conveyor Manufacturer for Your Industry

Selecting the right manufacturer is a critical decision that can impact your long-term operational success. A reliable manufacturer not only provides quality equipment but also ensures a smooth procurement experience from consultation to post-installation support.

Here are some factors to consider when choosing among slat conveyor manufacturers:

Industry Experience and Portfolio

Evaluate the manufacturer’s portfolio to see the diversity and scale of the projects they have handled. An experienced manufacturer understands the unique needs of various industries and can deliver tailored solutions.

Engineering Expertise and Design Capability

The quality of design and engineering determines the efficiency of the conveyor system. Make sure the manufacturer has a dedicated team of engineers who can offer detailed layouts, CAD drawings, and simulations.

Material Quality and Durability

Inspect the materials used for slats and frame construction. The best manufacturers use corrosion-resistant metals and high-grade plastics that can withstand demanding environments.

Compliance with Standards

Ensure that the conveyor systems meet international safety and quality standards, such as ISO certifications, CE marking, or other relevant compliance requirements.

After-Sales Service and Support

A manufacturer’s role doesn’t end after installation. Look for those who provide maintenance support, spare parts availability, and technical assistance to minimize downtime.

Customization Options

Your process may require specialized conveyor configurations. Choose manufacturers who offer flexibility in design, dimensions, and features such as side guards, sensors, and control integration.

Why Vikas Pumps Stands Out as a Trusted Slat Conveyor Manufacturer

At Vikas Pumps, we pride ourselves on being among the most trusted slat conveyor manufacturers in India. With decades of experience in designing and delivering high-performance material handling solutions, we have become a reliable partner for industries across the country and beyond.

Our slat conveyors are engineered to deliver smooth performance, even in the most demanding conditions. Every system is built with precision, using premium materials and modern manufacturing practices. From single-line conveyors to complex, integrated solutions, we serve a wide array of sectors including automotive, bottling, chemical, food processing, and more.

We don’t just supply equipment—we deliver reliability, innovation, and long-term value.

Key Strengths of Vikas Pumps as Slat Conveyor Manufacturers

-

Customized Solutions: Every conveyor is designed according to the client’s specific requirements.

-

Advanced Manufacturing Facilities: We use state-of-the-art technology and high-grade raw materials for exceptional quality.

-

On-Time Delivery: Our strong logistics and project management ensure timely completion and commissioning.

-

Competitive Pricing: We offer the best value by combining top-quality products with cost-effective solutions.

-

Expert Team: Our engineers and technicians are trained to provide seamless execution from design to installation.

Future of Slat Conveyor Manufacturing in India

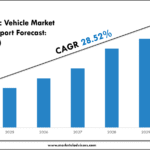

The future for slat conveyor manufacturers in India looks promising, driven by growing industrial automation, government support, and the increasing need for efficient logistics. As industries look for ways to reduce manual labor, improve safety, and enhance throughput, the demand for customized and smart conveyor systems will continue to rise.

Manufacturers will play a pivotal role by adopting IoT, AI-based monitoring, and predictive maintenance features into their conveyor designs. Green manufacturing practices and energy-efficient systems will also shape the future landscape.

As global markets open up to Indian engineering solutions, we expect slat conveyor manufacturers to become key players not only within India but also on the global stage.

Conclusion

Slat conveyors are the backbone of industrial automation and precision material handling. With their rugged design, flexible configurations, and ability to handle complex products, they remain indispensable for modern industries. Choosing the right manufacturer ensures not only product quality but also peace of mind, efficiency, and long-term savings.

As one of the leading slat conveyor manufacturers in India, Vikas Pumps stands ready to support your business with world-class conveyor systems built for excellence. Whether you need a standard solution or a customized system tailored to your unique processes, we are committed to delivering performance and value every step of the way.

Explore our complete range of slat conveyors and discover how Vikas Pumps can help you move your materials—and your business—forward.

- Slat Conveyor Manufacturers – Trusted Experts in India

- Looking for reliable slat conveyor manufacturers in India? Get high-performance, custom-built conveyors for your industrial needs. Trusted by top industries.

- Slat Conveyor Manufacturers, Slat Conveyor Manufacturers in India, Industrial Slat Conveyors, Custom Slat Conveyor Systems, Vikas Pumps

Related posts:

Used Cars for Sale in Japan: Your Complete Guide with Nobuko Japan

Used Cars for Sale in Japan: Your Complete Guide with Nobuko Japan

Introduction to Puncture Repair Services in Peterborough, UK

Introduction to Puncture Repair Services in Peterborough, UK

Mobile Tyre Fitting: A Brief and Comprehensive Guide Tips…

Mobile Tyre Fitting: A Brief and Comprehensive Guide Tips…

Orion Amplifiers: The Uncompromising Powerhouses Driving Next-Level Car Audio

Orion Amplifiers: The Uncompromising Powerhouses Driving Next-Level Car Audio

Fast & Free Car Removal Canterbury – Top Cash with Kiwiautowrecker

Fast & Free Car Removal Canterbury – Top Cash with Kiwiautowrecker

India Electric Vehicle Market Direction and Outlook (2025–2030)

India Electric Vehicle Market Direction and Outlook (2025–2030)

Expert Rubbish Removal Tips for Roxburgh Park Locals from OSOM Skip Bin Hire

Expert Rubbish Removal Tips for Roxburgh Park Locals from OSOM Skip Bin Hire

BGA Workstation: Essential Guide to Precision Soldering and Rework

BGA Workstation: Essential Guide to Precision Soldering and Rework