Tapered bearing manufacturers ensure load-bearing durability through a combination of precise engineering, material excellence, and rigorous quality control. The process starts with selecting high-grade alloy steels known for their strength and fatigue resistance. Manufacturers employ advanced heat treatment methods like case hardening to enhance wear resistance and load capacity under both radial and axial loads. Precision machining and grinding techniques are used to maintain exact dimensional tolerances, ensuring smooth operation and minimal friction. Additionally, manufacturers conduct extensive testing—including load, fatigue, and vibration tests—to verify performance under extreme conditions. These measures collectively ensure that tapered bearings can withstand heavy-duty applications over long operational lifespans without premature failure.

How Technology Is Reshaping the Tapered Bearing Manufacturing Sector

Technology is reshaping the tapered bearing manufacturing sector by streamlining production, improving precision, and boosting product performance. Modern manufacturing facilities are adopting CNC machining, automated grinding, and robotic assembly to achieve tight tolerances and consistent quality. Computer-aided design (CAD) and simulation tools are used to create more efficient bearing geometries tailored to specific load and speed conditions. Additionally, real-time data monitoring through IoT sensors enables predictive maintenance and minimizes downtime. These innovations not only reduce manufacturing costs but also ensure higher durability and reliability of tapered bearings, making Tapered bearing manufacturer more competitive in global markets.

Certifications That Define a Reliable Tapered Bearing Manufacturer

Certifications play a crucial role in identifying a reliable tapered bearing manufacturer, as they reflect adherence to internationally recognized quality, safety, and environmental standards. Key certifications include ISO 9001 for quality management, IATF 16949 for automotive sector compliance, and ISO 14001 for environmental management. These certifications ensure that the manufacturer follows stringent production protocols, continuous process improvement, and robust testing measures. Additionally, RoHS compliance and CE marking are important for export-oriented businesses, indicating that the products meet global safety and environmental norms. A manufacturer holding these certifications demonstrates commitment to delivering precision-engineered, high-performance tapered bearings consistently across markets.

- How Tapered Bearing Manufacturers Ensure Load-Bearing Durability

- Discover how tapered bearing manufacturers enhance durability using precision engineering, heat treatment, and testing.

- Tapered Bearing Manufacturer

Related posts:

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

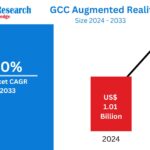

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

Embracing the Call — Supporting Life Through Christian Faith

Embracing the Call — Supporting Life Through Christian Faith

Make Waves on Your Birthday with SunFunFTL’s Luxury Boat Rentals in Fort Lauderdale

Make Waves on Your Birthday with SunFunFTL’s Luxury Boat Rentals in Fort Lauderdale

Biodegradable Packaging Trends Across Asia-Pacific & Global Markets

Biodegradable Packaging Trends Across Asia-Pacific & Global Markets

How to Use Magazine WordPress Themes to Create a Unique News Experience

How to Use Magazine WordPress Themes to Create a Unique News Experience