In the world of industrial infrastructure, power delivery is often seen but seldom noticed — until it fails. High Tension (HT) cables form the unseen yet indispensable network that powers factories, refineries, data centers, and cities. But while these cables are built for endurance, they are not immune to deterioration.

Unexpected cable malfunctions can paralyze operations, disrupt production schedules, and create serious safety hazards. This is where the concept of HT cable condition monitoring becomes a vital part of preventive maintenance strategies.

Today, organizations are realizing that safeguarding their electrical network is not just about fixing problems — it’s about foreseeing them.

Why Do HT Cables Degrade Over Time?

HT cables operate in demanding environments — often buried underground, submerged in water, or running across industrial landscapes exposed to varying weather conditions.

Several factors contribute to their gradual decline:

- Aging insulation materials

- Water penetration through joints or damaged sheathing

- Electrical stress due to overloading

- Chemical exposure from oils, solvents, or corrosives

- Physical damage during installation or repairs

- Thermal cycling — repeated heating and cooling from fluctuating loads

These hidden stressors slowly weaken the cable’s insulation system, setting the stage for faults that can cause expensive outages and equipment loss.

Proactive Monitoring: Moving Beyond Reactive Repairs

Traditional maintenance models waited for a cable to fail before action was taken — a practice that now seems outdated and inefficient. Modern asset management focuses on early detection, risk mitigation, and extending the operational lifespan of infrastructure.

This is why diagnostic evaluations of HT cables are now considered essential — they provide crucial insight into the internal health of cables before faults escalate into disasters.

Key Testing Techniques That Protect HT Cable Networks

Several sophisticated testing methodologies have emerged to assess the integrity of HT cables. Each serves a unique purpose in detecting specific forms of degradation.

- VLF (Very Low Frequency) Testing

Instead of using power frequency voltage, VLF testing uses lower frequencies to assess insulation performance under stress conditions, revealing potential weaknesses.

- Tan Delta (Loss Angle) Analysis

This test evaluates insulation efficiency by measuring the resistive losses within the dielectric material. A rising Tan Delta value is a clear red flag for moisture ingress or insulation fatigue.

- Partial Discharge (PD) Detection

PD testing identifies micro-level discharge activity within the cable insulation — often an early symptom of voids, cracks, or contamination.

- Time Domain Reflectometry (TDR)

TDR technology is akin to cable “radar” — sending pulses down the length of the cable and analyzing reflected signals to pinpoint faults or irregularities.

- Insulation Resistance Measurement

This classic test verifies the insulation’s ability to resist current leakage, providing insight into moisture presence or insulation breakdown.

Benefits of HT Cable Diagnostics: A Strategic Advantage

Regular diagnostic assessments of HT cables offer more than just technical information — they provide operational security, financial savings, and peace of mind.

- Elimination of Unscheduled Outages

Early detection of cable weaknesses ensures that maintenance can be performed during planned downtimes, avoiding costly production halts.

- Enhanced Safety for Personnel & Equipment

Identifying faults before failure protects workers from electrical hazards and prevents collateral damage to sensitive machinery.

- Optimized Maintenance Expenditure

Condition-based maintenance is far more cost-efficient than emergency interventions or full cable replacements.

- Prolonged Asset Life

With timely repairs and monitoring, the functional life of HT cables can be extended well beyond their standard operational expectancy.

- Data-Driven Maintenance Planning

Over time, diagnostic records provide valuable trends and patterns, enabling predictive analytics and smarter maintenance scheduling.

Future of HT Cable Monitoring: Smart Grids & Real-Time Surveillance

Emerging technologies are revolutionizing the way we manage electrical infrastructure. Smart sensors embedded within cable systems can continuously monitor temperature, insulation resistance, and electrical performance, transmitting real-time alerts when anomalies are detected.

This evolution towards automated, real-time cable health surveillance represents the future of industrial power management — enabling industries to stay one step ahead of potential failures.

Challenges to Consider

While the advantages of HT cable diagnostic testing are substantial, certain challenges persist:

- Specialized skills are required to conduct and interpret test results accurately.

- Initial investment in testing technology can be high for smaller facilities.

- Testing must be carefully integrated into operational schedules to minimize disruptions.

Despite these hurdles, the long-term savings and risk reduction make the investment worthwhile for any industry relying on a stable power supply.

Final Takeaway: Prevention is Power

HT cables may lie buried beneath our feet or hidden behind walls, but their role is nothing short of critical. Waiting for them to fail is not a strategy — it’s a liability.

HT Cable diagnostic testing transforms maintenance from guesswork to precision science. It allows industries to detect, diagnose, and correct minor faults before they snowball into major breakdowns.

In a world driven by electricity, cable health management is not just a technical practice — it’s a business necessity.

After all, true power doesn’t just come from what flows through your cables — it comes from knowing your cables will never let you down.

- Preventing Cable Failure: The Importance of HT Cables Diagnostic Testing

- In the world of industrial infrastructure, power delivery is often seen but seldom noticed — until it fails. High Tension (HT) cables form the unseen yet indispensable network that powers factories, refineries, data centers, and cities. But while these cables are built for endurance, they are not immune to deterioration.

- HT Cable diagnostic testing

Related posts:

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

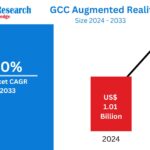

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

Embracing the Call — Supporting Life Through Christian Faith

Embracing the Call — Supporting Life Through Christian Faith

Make Waves on Your Birthday with SunFunFTL’s Luxury Boat Rentals in Fort Lauderdale

Make Waves on Your Birthday with SunFunFTL’s Luxury Boat Rentals in Fort Lauderdale

Biodegradable Packaging Trends Across Asia-Pacific & Global Markets

Biodegradable Packaging Trends Across Asia-Pacific & Global Markets

How to Use Magazine WordPress Themes to Create a Unique News Experience

How to Use Magazine WordPress Themes to Create a Unique News Experience