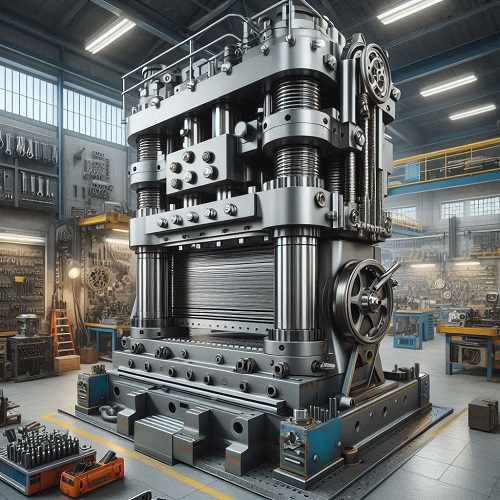

Indian fabricators prefer hydraulic press brake machines due to their unmatched versatility, precision, and reliability in handling diverse bending applications across industries. With the growing demand for high-quality metal components in sectors like automotive, construction, and infrastructure, hydraulic press brakes offer consistent performance, reduced manual intervention, and the ability to work with a wide range of materials and thicknesses. Their adaptability to CNC controls and energy-efficient operation makes them ideal for both small workshops and large-scale manufacturing units in India. Moreover, the availability of locally manufactured machines ensures cost-effectiveness and easy maintenance, further cementing their popularity among Indian metal fabricators.

The Rise of Hydraulic Press Brake Technology

The rise of hydraulic press brake technology marks a significant shift in the metalworking industry, bringing greater precision, control, and efficiency to the bending process. Unlike traditional mechanical systems, hydraulic press brakes use fluid pressure to apply consistent force, allowing for smoother, more accurate bends even in thick or complex metal sheets. This advancement has enabled manufacturers to meet the growing demand for high-quality, customized components across automotive, aerospace, construction, and heavy engineering sectors. With the integration of CNC systems, modern hydraulic press brakes offer programmable accuracy and repeatability, reducing setup time and increasing productivity. As technology continues to evolve, hydraulic press brakes are becoming the cornerstone of next-generation fabrication solutions.

Applications of Hydraulic Press Brakes in Indian Manufacturing

Hydraulic press brake machine india play a crucial role in manufacturing sectors, powering a wide range of applications across key sectors such as automotive, agriculture, construction, and electrical equipment. These machines are widely used for bending and shaping sheet metal into components like chassis parts, enclosures, brackets, control panels, and structural frames. In the automotive industry, they help produce precision parts for vehicles, while in agriculture, they assist in fabricating equipment like plows and harrows. Their ability to deliver accurate and repeatable bends makes them indispensable for small-scale workshops and large industrial units alike. As India continues to expand its manufacturing capabilities under initiatives like “Make in India,” hydraulic press brakes remain a vital asset driving quality, scalability, and innovation.

How Hydraulic Press Brake Machines Work: A Beginner’s Guide

Hydraulic press brake machines operate by using hydraulic force to bend and shape metal sheets with precision. At the heart of the system are hydraulic cylinders that apply pressure to a ram, which in turn presses a punch into the metal sheet placed over a die. As the ram descends, the metal is forced into the die, creating a clean, accurate bend. The amount of pressure, bend angle, and position can be precisely controlled, especially in modern CNC-equipped machines. This allows operators to produce consistent, high-quality bends across various materials and thicknesses. For beginners, understanding this process is key to mastering sheet metal fabrication and maximizing the machine’s potential in industrial applications.

- Why Indian Fabricators Prefer Hydraulic Press Brakes

- Discover why Indian fabricators choose hydraulic press brakes for precision, efficiency, and versatile metal bending solutions.

- Hydraulic Press Brakes

Related posts:

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

Embracing the Call — Supporting Life Through Christian Faith

Embracing the Call — Supporting Life Through Christian Faith

Make Waves on Your Birthday with SunFunFTL’s Luxury Boat Rentals in Fort Lauderdale

Make Waves on Your Birthday with SunFunFTL’s Luxury Boat Rentals in Fort Lauderdale

Biodegradable Packaging Trends Across Asia-Pacific & Global Markets

Biodegradable Packaging Trends Across Asia-Pacific & Global Markets

How to Use Magazine WordPress Themes to Create a Unique News Experience

How to Use Magazine WordPress Themes to Create a Unique News Experience