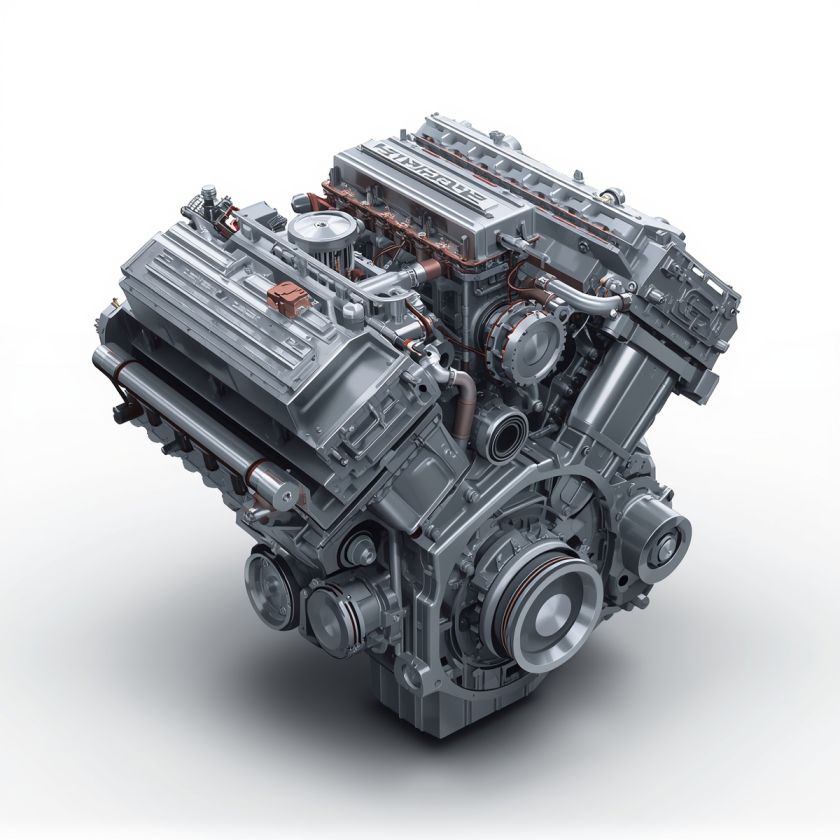

The LM7 engine, introduced by General Motors in 1999, is one of the most notable members of the Generation III small-block V8 engine family, commonly referred to as the series. Specifically designed for use in trucks and SUVs, the LM7 is a 5.3-liter, naturally aspirated V8 that blends durability, efficiency, and affordability. Over its production span from 1999 to 2007, the LM7 powered a wide range of Chevrolet, GMC, and Cadillac vehicles, earning a reputation as a dependable workhorse in both stock and modified forms.

At its core, the LM7 engine features a displacement of 5.3 liters (325 cubic inches), achieved with a bore of 96 mm (3.78 inches) and a stroke of 92 mm (3.62 inches). The block itself is made of cast iron, which provides excellent strength and durability under heavy loads. This makes the LM7 well-suited for truck and towing applications, though it also carries some extra weight compared to its aluminum-block counterparts like the LM4 and L33.

At its core, the LM7 engine features a displacement of 5.3 liters (325 cubic inches), achieved with a bore of 96 mm (3.78 inches) and a stroke of 92 mm (3.62 inches). The block itself is made of cast iron, which provides excellent strength and durability under heavy loads. This makes the LM7 well-suited for truck and towing applications, though it also carries some extra weight compared to its aluminum-block counterparts like the LM4 and L33.

The cylinder heads are cast aluminum with cathedral-style intake ports, a hallmark of early LS-based engines. These heads allow for strong airflow while keeping weight manageable. The compression ratio is approximately 9.5:1, which permits the use of regular pump gasoline while still producing efficient power. In stock form, the LM7 produces around 270–295 horsepower and 315–335 lb-ft of torque, depending on the year and application. This output was more than sufficient for the light trucks and SUVs of the early 2000s.

Fuel delivery is managed through sequential fuel injection, and ignition relies on a coil-on-plug system, both of which were advanced technologies when the LM7 debuted. These improvements, combined with electronic throttle control in later years, gave the LM7 improved reliability, better emissions control, and more precise engine management compared to the older small-block Chevrolet engines it replaced.

Internally, the LM7 uses a cast crankshaft and powdered-metal connecting rods, both designed to withstand the rigors of daily truck use. While not as performance-oriented as some forged components, these internals have proven reliable for stock use and even moderate aftermarket upgrades. The camshaft profile is relatively mild, focusing on low- and mid-range torque rather than high-RPM horsepower, reflecting its intended role as a truck engine.

The LM7 also benefits from the modular design of the LS family. Many performance parts, such as intake manifolds, cylinder heads, and camshafts, are interchangeable across other LS engines, giving the LM7 a unique position as both a durable OEM engine and a solid foundation for performance builds. Its affordability and widespread availability in junkyards have made it a favorite among enthusiasts performing LS swaps in everything from muscle cars to off-road vehicles.

In summary, the LM7 is a versatile 5.3L V8 that blends strength, reliability, and adaptability. While designed as a truck engine, its role has expanded far beyond that thanks to its LS heritage, making it a cornerstone of both OEM utility and aftermarket performance culture.

In stock form, the LM7 delivered 270–295 horsepower and up to 335 lb-ft of torque, numbers that made it ideal for the half-ton trucks and SUVs of its era. Vehicles like the Chevrolet Silverado, GMC Sierra, Tahoe, and Suburban benefitted from the LM7’s strong mid-range torque, making towing and hauling far more manageable than with older V8 options. Reliability was another key strength—these engines routinely surpass 200,000 miles with only basic maintenance, cementing their reputation as dependable workhorses.

Where the LM7 truly shines, however, is in the aftermarket. Because it shares its architecture with the LS engine family, it accepts a huge range of performance upgrades. Enthusiasts frequently install hotter camshafts, aftermarket cylinder heads, and high-flow intake manifolds to unleash significant gains. A simple cam swap and tuning can push the LM7 well over 350 horsepower, while more extensive builds involving boost—turbochargers or superchargers—can take the iron-block engine past 600 horsepower with relative ease. Its cast-iron construction, while heavier than aluminum-block variants, offers excellent strength for high-boost applications, making the LM7 a budget-friendly platform for forced induction builds.

The affordability and availability of the LM7 have also driven its popularity in engine swaps. Junkyards across North America are full of LM7-equipped trucks, making it one of the most accessible LS-based engines on the market. As a result, it has found its way into classic muscle cars, drift builds, hot rods, and even off-road rigs. LS swap kits and aftermarket support are abundant, allowing builders to adapt the LM7 to nearly any platform with relative ease.

Another major advantage is the LM7’s versatility in fueling and tuning. The factory fuel injection system can be retained with standalone engine management, or it can be converted to carburetion for retro-style builds. With coil-on-plug ignition and modern electronics, tuners have precise control over spark and fuel delivery, ensuring both reliability and performance under demanding conditions.

- LM7 improved reliability, better emissions control

- Over its production span from 1999 to 2007, the LM7 powered a wide range of Chevrolet, GMC, and Cadillac vehicles, earning a reputation as a dependable workhorse in both stock and modified forms.

- AllAmericanMotorsHub

Related posts:

Dominate Search Rankings with the Best Google Stacking Services by VTraffic

Dominate Search Rankings with the Best Google Stacking Services by VTraffic

Your Trusted Digital Agency: What Makes a Marketing Company Stand Out in 2025

Your Trusted Digital Agency: What Makes a Marketing Company Stand Out in 2025

Global Pharmaceutical Solvents Market Size, Share, Key Players, Trends, Sales, Supply, Demand, Analysis and Forecast 2032

Global Pharmaceutical Solvents Market Size, Share, Key Players, Trends, Sales, Supply, Demand, Analysis and Forecast 2032

Expert SEO Services in New York – Dominate the Digital Landscape

Expert SEO Services in New York – Dominate the Digital Landscape

How the eCommerce Market is Evolving in 2025: Trends to Watch

How the eCommerce Market is Evolving in 2025: Trends to Watch

Freelance Illustrators for Hire: Tips to Choose the Right One for Your Style

Freelance Illustrators for Hire: Tips to Choose the Right One for Your Style

How Brands Gain Lasting Impact Through News Sites Like Lensa Nusantara

How Brands Gain Lasting Impact Through News Sites Like Lensa Nusantara

Captivate Audiences with Professional Motion Graphic Design Services in Lahore

Captivate Audiences with Professional Motion Graphic Design Services in Lahore