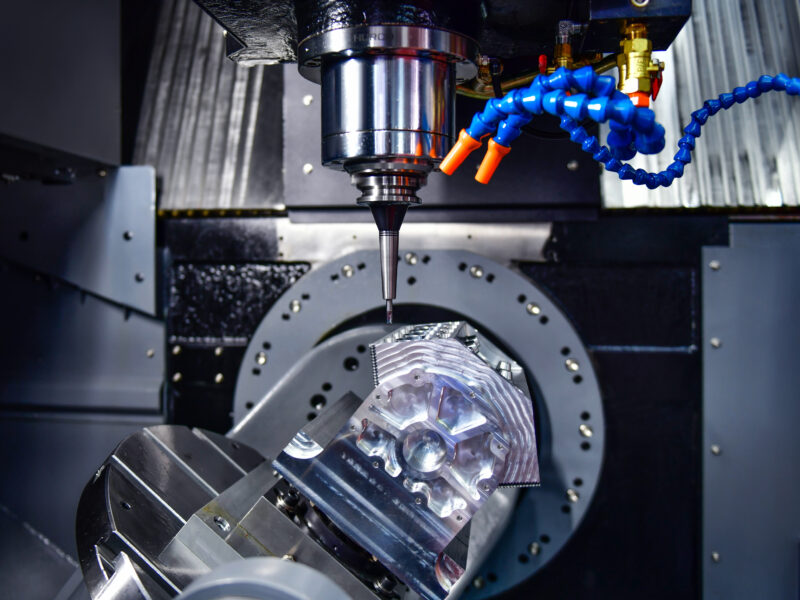

Understanding a CNC machining quote is essential for making informed decisions about part production, budgeting, and supplier selection.

Whether you’re ordering a one-off prototype or a large batch of components, a CNC quote breaks down the costs involved—from material to machining time and finishing.

However, these quotes can be complex if you’re unfamiliar with how CNC operations are priced. This guide will help you interpret each line item in a CNC machining quote and identify the key factors that affect total cost.

What Is a CNC Machining Quote?

A CNC machining quote is an estimate provided by a manufacturer or machining service detailing the expected cost to produce your part.

It’s typically based on your CAD file, technical drawing, and project specifications such as quantity, material, surface finish, and delivery timeline.

The quote helps you:

-

Understand the production cost breakdown

-

Compare vendors on price and capability

-

Make trade-off decisions between design complexity and cost

-

Plan your budget and project schedule

Let’s explore the main components you’ll find in a CNC quote and what influences them.

1. Material Cost

Material cost refers to the raw material required to manufacture your part.

It’s typically calculated based on:

-

Type of material (e.g., aluminum, steel, titanium, plastic)

-

Dimensions of the raw stock needed

-

Material grade and certification requirements (e.g., medical-grade, aerospace-certified)

-

Waste generated during machining

Example: Machining a part from a titanium billet will cost significantly more than machining the same part from aluminum due to both the material price and tool wear impact.

Some vendors also include material sourcing fees or cutting and prepping charges for bars, sheets, or blocks.

2. Machining Time

This is usually the largest portion of your CNC quote.

Machining time includes the actual number of machine hours required to complete the job and is influenced by:

-

Part complexity

-

Number of operations (milling, turning, drilling)

-

Tolerances and surface finish requirements

-

Toolpath strategies (e.g., high-speed machining, 5-axis milling)

-

Machine type used (3-axis vs. 5-axis or Swiss lathe)

More complex parts with tight tolerances, fine threads, and multi-sided machining will increase run time, which directly increases cost.

Pro Tip: Simpler designs with standard features can reduce machine time and save significantly on your quote.

3. Setup and Programming

Setup refers to preparing the CNC machine for your specific job.

This includes:

-

Installing tools and fixtures

-

Zeroing the machine to your part’s dimensions

-

CAM programming to generate G-code from your CAD file

-

Creating toolpaths and simulations

Setup is often a fixed one-time fee for each job, and it can be expensive for small-quantity orders. For high-volume runs, the setup cost is amortized over more units, lowering the per-part cost.

Jobs requiring multi-axis machining or complex workholding will have higher setup fees.

4. Tooling and Consumables

Some quotes include charges for custom tooling, especially if your part requires special:

-

Thread mills or taps

-

Radius or form cutters

-

Carbide inserts for hard materials

For standard tools, costs are typically factored into machine time. However, if your part demands custom fixturing or special tool geometries, the quote may list these separately.

Additionally, machining abrasive or hard materials (e.g., titanium, Inconel) causes faster tool wear, which may increase consumable costs.

5. Tolerances and Surface Finish

The tighter the tolerance, the longer it takes to machine.

Achieving high precision (e.g., ±0.005 mm) may require additional passes, slower feed rates, and extra inspection—all of which increase time and cost.

Surface finish requirements also affect the quote:

-

Standard finish (Ra 3.2 µm): Typically included in base price

-

Fine finish (Ra 1.6 or lower): Requires additional passes or polishing

-

Mirror finish or anodizing prep: May add a secondary operation

Clearly specifying acceptable tolerances and finish can help avoid unnecessary machining and reduce cost.

6. Secondary Processes and Finishing

Many parts require operations beyond cutting and shaping. These can include:

| Process | Typical Impact on Cost |

|---|---|

| Deburring & edge smoothing | Low to moderate |

| Anodizing or plating | Moderate |

| Heat treating | Moderate to high |

| Laser engraving or marking | Low to moderate |

| Assembly or kitting | Varies by complexity |

Each of these steps may be quoted separately or bundled under a “finishing” or “post-processing” line item.

7. Quantity and Batch Size

The more units you order, the lower the per-part cost.

That’s because:

-

Setup and programming costs are spread across more parts

-

Toolpaths are reused

-

Bulk material purchasing reduces raw cost

-

Machine time is optimized in longer production runs

Quotes often include tiered pricing (e.g., 1–10 units, 11–50 units, etc.), so it’s smart to ask how your price changes with order quantity.

8. Quality Inspection and Compliance

If your part requires:

-

CMM (coordinate measuring machine) inspection

-

Material certification (e.g., ISO 10204, DFARS compliance)

-

First Article Inspection Report (FAIR)

-

PPAP or AS9102 documents

…these may carry extra charges depending on documentation complexity and reporting format.

Medical, aerospace, and defense applications almost always require some level of compliance and traceability, which will show up in the quote.

9. Packaging and Shipping

For many CNC jobs, shipping is quoted separately. You might see:

-

Crating or protective packaging costs

-

Labeling or barcoding fees for parts in kits

-

Expedited or international shipping options

If your parts are fragile, require individual wrapping, or must follow export rules, these costs will appear near the end of the quote.

10. Design Feedback and File Handling

Some machining services charge for reviewing or modifying CAD files, especially when:

-

Files are incomplete or lack tolerances

-

Drawings require translation from 2D to 3D

-

Geometry needs DFM (Design for Manufacturability) adjustment

Tip: Clean, well-annotated files reduce quoting time and eliminate potential errors during production. Consider using services that offer CNC cutting design support to optimize part geometry and reduce costs.

Summary: CNC Quote Breakdown Checklist

| Cost Factor | Influences |

|---|---|

| Material Cost | Type, size, waste, certifications |

| Machining Time | Complexity, operations, tolerances |

| Setup/Programming | CAM time, fixturing, machine prep |

| Tooling and Wear | Special cutters, abrasive materials |

| Surface Finish | Required Ra, polishing, aesthetics |

| Secondary Processes | Coatings, treatments, engraving |

| Quantity | Volume discounts, batch size tiers |

| Quality & Compliance | Documentation, inspection, traceability |

| Packaging & Shipping | Fragility, export, part labeling |

| CAD File Handling | Rework, translation, DFM analysis |

Final Thoughts

Reading a CNC quote doesn’t have to be confusing. When you understand the cost drivers—from material selection to tolerances and secondary finishes—you can confidently evaluate vendors, optimize your designs, and plan smarter production strategies.

Always review your quote carefully and ask for clarification if any item is unclear or unexpected. A transparent CNC partner will help you understand exactly what you’re paying for—and how to improve your design for cost efficiency.

Need help reviewing or designing a CNC part for better pricing? Explore expert CNC cutting design services that can guide you through best practices before you even request a quote.

- How to Read a CNC Machining Quote: A Breakdown of Cost Factors

- Learn how to read a CNC machining quote by understanding material, setup, tooling, and machining cost factors. Use this guide to optimize pricing and compare vendors confidently.

- How to Read a CNC Machining Quote

Related posts:

Why KBH Games Is Perfect for Family-Friendly Online Entertainment

Why KBH Games Is Perfect for Family-Friendly Online Entertainment

Build a Seamless School Portal with These Powerful Templates

Build a Seamless School Portal with These Powerful Templates

Samsung Galaxy S24 Ultra Price in Pakistan: A Closer Look at the Mid-Range Marvel

Samsung Galaxy S24 Ultra Price in Pakistan: A Closer Look at the Mid-Range Marvel

The Ultimate Web Development Checklist for Building High-Performance Digital Experiences

The Ultimate Web Development Checklist for Building High-Performance Digital Experiences

How Ecommerce ERP Transforms Inventory and Order Management – Rholab

How Ecommerce ERP Transforms Inventory and Order Management – Rholab

Benefits of AI-powered CCTV Cameras for Business Surveillance

Benefits of AI-powered CCTV Cameras for Business Surveillance

Top App Development Agency UK – Transforming Ideas into Apps

Top App Development Agency UK – Transforming Ideas into Apps

Transforming Oil and Gas Operations in Qatar with Microsoft Dynamics 365 Supply Chain Management

Transforming Oil and Gas Operations in Qatar with Microsoft Dynamics 365 Supply Chain Management