Commercial boilers are the backbone of heating structures in office buildings, manufacturing facilities, hospitals, faculties, and infinite other commercial properties. These workhorses perform across the clock for the duration of heating seasons, supplying consistent warm temperature and warm water that keeps corporations walking easily. However, like every mechanical gadget, business boilers have finite lifespans, and knowing whilst to replace in preference to restore can store your commercial enterprise thousands of bucks at the same time as stopping costly downtime and emergency conditions.

The selection among restore and replacement isn’t always straightforward. While minor troubles can frequently be resolved with targeted maintenance, certain warning signs suggest that your boiler has reached the stop of its useful life. Recognizing those important signs early allows you to devise for substitute strategically, fending off the disruption and price of emergency breakdowns for the duration of top heating season.

Understanding the Repair vs. Replacement Decision

Before diving into particular warning symptoms, it’s crucial to understand the factors that have an effect on whether or not repair or replacement makes economic feel. Generally, if repair prices exceed 50% of the replacement cost, or if your boiler is coming near or has exceeded its anticipated lifespan, replacement becomes the extra inexpensive choice. Commercial boilers typically ultimate 15-30 years depending on the sort, usage, and renovation history.

The “50% rule” serves as a helpful guiding principle, but different elements complicate this choice. Energy performance upgrades, changing heating demands, regulatory compliance requirements, and the supply of alternative parts all have an impact on whether substitute makes feel even for apparently repairable troubles.

Sign #1: Escalating Energy Bills Despite Normal Usage

One of the most telling signs that your commercial boiler wishes alternative is a regular boom in strength charges that can’t be attributed to growing gasoline prices or accelerated heating needs. When a boiler’s performance degrades notably, it consumes greater fuel to produce the identical quantity of heat, immediately impacting your backside line.

Efficiency degradation regularly happens step by step, making it clean to overlook until the financial impact turns into massive. A boiler that after done eighty five% performance may drop to 70% or decrease because of inner corrosion, scale buildup, or thing wear. This 15-point efficiency drop translates to kind of 20% better fuel fees—a extensive fee for commercial operations.

Modern high-performance commercial boilers can attain 90-ninety five% efficiency ratings, compared to older devices working at 70-80%. The gasoline savings from replacement frequently justify the funding inside five-7 years, in particular for centers with excessive heating needs. Additionally, application rebates and tax incentives for high-efficiency system can similarly enhance the monetary case for substitute.

If your power bills have accelerated with the aid of 20% or more during the last few years without corresponding adjustments in usage styles or gasoline charges, your boiler’s declining performance in all likelihood warrants substitute in preference to persisted repairs.

Sign #2: Frequent Breakdowns and Repair Calls

When your protection crew or carrier contractors emerge as normal visitors because of routine boiler issues, replacement deserves extreme attention. Frequent breakdowns imply systemic issues that repair can’t appropriately cope with, and the cumulative cost of more than one carrier calls frequently exceeds replacement fees.

Beyond direct repair prices, frequent breakdowns convey hidden charges that significantly impact your business. Each breakdown risks disrupting operations, affecting worker consolation and productivity, and potentially detrimental temperature-touchy gadget or inventory. Emergency service calls at some stage in nights, weekends, or vacations command premium prices, in addition increasing expenses.

Aging boilers require more and more luxurious repairs as additives put on out and substitute components emerge as more difficult to find. Older boiler models may additionally require custom fabrication of parts or complete issue assemblies, driving repair costs properly past low-priced tiers. When restore prices for a unmarried incident approach $five,000-$10,000, or when you’re scheduling monthly service calls, replacement typically gives higher long-term price.

Consider also the opportunity fee of control time spent coordinating upkeep, tracking unreliable device, and managing the results of heating system disasters. This administrative burden alone frequently justifies alternative for busy business operations.

Sign #3: Inability to Maintain Consistent Temperatures

Commercial buildings require reliable, consistent heating to keep cushty operating situations and defend touchy gadget. When your boiler can now not preserve constant temperatures at some stage in your facility, it signals fundamental problems that repair can’t clear up.

Temperature inconsistencies happen in numerous ways: some areas of your building may be too hot at the same time as others continue to be bloodless, temperatures may additionally vary dramatically for the duration of the day, or the system can also warfare to reach favored temperatures throughout bloodless weather. These problems frequently stem from declining warmth exchanger efficiency, inadequate move, or control machine issues which can be symptomatic of standard machine deterioration.

Inconsistent heating creates more than one enterprise troubles past comfort worries. Temperature fluctuations can damage sensitive gadget, affect product satisfactory in manufacturing settings, impact worker productivity and pride, and potentially violate regulatory necessities for sure industries like healthcare or food carrier.

Modern industrial boilers comprise superior manage systems that precisely control temperature and optimize performance. These structures can zone heating, modulate output based on demand, and integrate with constructing control structures for surest overall performance. If your current boiler lacks these skills or can now not keep regular performance, replacement with current device can clear up more than one operational challenges concurrently.

Sign #4: Visible Corrosion, Leaks, or Structural Damage

Physical deterioration of your boiler system offers clear evidence that replacement is essential. Unlike minor mechanical problems that restore can cope with, structural issues compromise the whole device’s integrity and safety.

Corrosion represents one of the maximum extreme issues for business boilers. External corrosion on the boiler shell, heat exchanger, or piping suggests that the system’s structural integrity is compromised. Internal corrosion, whilst less visible, causes comparable problems and frequently manifests thru declining performance, frequent repairs, or water exceptional problems.

Water leaks across the boiler, especially from the heat exchanger or most important vessel, sign critical problems that normally can’t be economically repaired. Heat exchanger alternative regularly expenses 60-80% of a complete boiler substitute, making new equipment the extra sensible desire. Additionally, ongoing leaks can motive water damage to surrounding equipment and building structures, creating additional legal responsibility and restore costs.

Rust, scale buildup, or mineral deposits for the duration of the system suggest terrible water best management and suggest full-size internal harm. While water treatment can prevent in addition deterioration, current harm generally calls for whole gadget alternative to repair right operation.

Cracks inside the warmness exchanger or boiler vessel represent instantaneous protection risks that require immediately shutdown and substitute. These structural screw ups can’t be repaired accurately and pose risks of catastrophic failure if operation maintains.

Sign #5: Age and Obsolescence Issues

The age of your industrial boiler performs a crucial role in restore as opposed to alternative decisions. Boilers drawing near or exceeding their expected lifespan of 20-25 years face a couple of challenges that make replacement more appealing than persevered maintenance.

Older boilers regularly fail to fulfill contemporary performance requirements, environmental regulations, and protection codes. Changes in building codes, emissions requirements, and performance requirements may also require widespread changes or complete substitute to keep compliance. These regulatory adjustments can force alternative irrespective of the boiler’s mechanical situation.

Parts availability will become more and more difficult for older equipment. Manufacturers stop components guide for older models, forcing reliance on aftermarket suppliers, rebuilt additives, or custom fabrication. These options regularly value greater than authentic elements while offering inferior reliability and overall performance.

Technological obsolescence additionally influences older boilers. Modern business boilers contain superior features like modulating burners, sophisticated manage systems, far off monitoring abilties, and integration with constructing control systems. These functions provide operational benefits, power financial savings, and maintenance benefits that older structures cannot suit.

Insurance and liability concerns may additionally desire alternative. Some insurance companies impose higher premiums or coverage obstacles for older boilers, in particular the ones exceeding 20 years of age. The risk of catastrophic failure and related liability will increase with age, making replacement a risk management method.

Making the Financial Case for Replacement

When multiple caution signs seem concurrently, the financial case for replacement usually becomes compelling. Consider the entire fee of ownership, including strength costs, upkeep charges, downtime costs, and the threat of emergency replacement in the course of peak heating season.

Emergency boiler replacement throughout iciness months regularly charges 20-30% greater than deliberate alternative in the course of off-season intervals. Emergency conditions restriction device alternatives, require expedited transport and set up, and regularly necessitate brief heating solutions that add sizeable expenses.

Planned replacement lets in you to take benefit of utility rebates, tax incentives, and manufacturer promotions that may considerably lessen net system prices. Many utilities provide significant rebates for high-performance business boilers, and federal tax credit might also apply to qualifying device.

Choosing the Right Replacement Strategy

When alternative turns into necessary, keep in mind your facility’s present day and future heating desires. Building expansions, technique modifications, or performance enhancements may additionally modify heating necessities. Modern high-performance boilers offer higher turndown ratios and modulating talents that may accommodate various loads greater correctly than older consistent-output units.

Evaluate special gasoline options at some point of alternative planning. Natural fuel, oil, propane, or even renewable options like biomass can also offer operational or price advantages depending in your place and facility necessities.

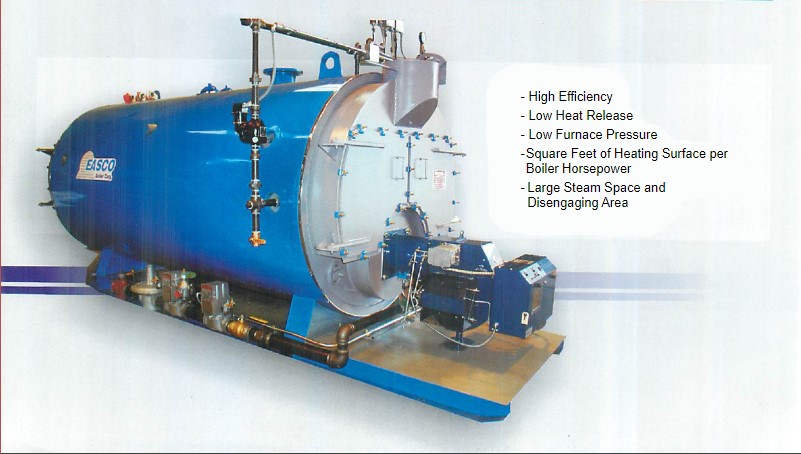

Superior Commercial Boiler Solutions for Every Application

When it’s time to update your commercial boiler, Supreme Boilers grants demonstrated reliability and extremely good performance throughout their complete product line. Their FST Series presents robust overall performance for worrying commercial applications, at the same time as the ESP Series offers superior condensing generation for maximum performance and lowest operating charges. For specialised industrial needs, the FPS Series can provide flexible overall performance, and the PLW Series guarantees reliable operation in challenging environments. The present day SM4 Series and SM5 Series represent the top of commercial boiler generation, incorporating advanced controls and superior efficiency rankings that dramatically lessen working charges even as ensuring dependable performance. With many years of industrial heating know-how, Supreme Boilers provides comprehensive answers that address all 5 substitute indicators discussed above, supporting you avoid high-priced maintenance and downtime via superior engineering and proven reliability.

Conclusion

Recognizing when your commercial boiler wishes substitute in place of repair protects your business from unexpected screw ups, reduces running fees, and ensures reliable heating on your facility. The five caution signs—escalating strength payments, frequent breakdowns, temperature inconsistencies, physical deterioration, and age-related obsolescence—often seem collectively as systems technique give up-of-existence.

Proactive replacement planning lets in you to preserve enterprise continuity at the same time as taking advantage of contemporary boiler era that offers superior efficiency, reliability, and manage competencies. While the upfront investment may additionally appear great, the long-term benefits of reliable heating, decreased strength costs, and minimized upkeep expenses usually justify replacement charges in the first few years of operation.

Don’t look forward to whole failure to pressure an emergency replacement selection. When a couple of warning signs and symptoms appear, consult with qualified industrial boiler specialists to evaluate your alternatives and broaden a replacement strategy that minimizes disruption at the same time as maximizing long-time period value to your enterprise.

- 5 Signs Your Commercial Boiler Needs Replacement (Not Just Repair)

- Recognizing those important signs early allows you to devise for substitute strategically, fending off the disruption and price of emergency breakdowns for the duration of top heating season.

- Commercial Boiler

Related posts:

Discover the Best Fence Installation Services in Omaha with Huskins Services LLC

Discover the Best Fence Installation Services in Omaha with Huskins Services LLC

Summer Solstice Party Ideas & Activities for a Magical Celebration | BizzCrave

Summer Solstice Party Ideas & Activities for a Magical Celebration | BizzCrave

At the Time of Booking: What to Keep in Mind During a Medical Emergency

At the Time of Booking: What to Keep in Mind During a Medical Emergency

Streamline Your Business with an Automated Employee Payroll System

Streamline Your Business with an Automated Employee Payroll System

How to Use Magazine WordPress Themes to Create a Unique News Experience

How to Use Magazine WordPress Themes to Create a Unique News Experience

What Should You Know Before Choosing a Book Printing Company?

What Should You Know Before Choosing a Book Printing Company?

Discovering the Right Office Furniture for Comfort and Productivity

Discovering the Right Office Furniture for Comfort and Productivity

Thermal Imaging: Revolutionizing Detection Through Infrared Technology

Thermal Imaging: Revolutionizing Detection Through Infrared Technology