In the world of aerospace manufacturing, precision, efficiency, and repeatability are everything. When you’re building complex components or assembling full aircraft structures, having a streamlined production process isn’t just helpful—it’s mission-critical. That’s where aerospace flow lines come in.

These specialized production systems are designed to keep everything moving smoothly from one stage to the next, improving throughput while maintaining exacting quality standards. Whether you’re new to the concept or want to optimize your current setup, understanding how Aerospace Flow Lines work—from design all the way to implementation—can be a game-changer for your operations.

Let’s break it down in a way that’s easy to follow.

What Are Aerospace Flow Lines?

Flow lines in aerospace are structured, linear production systems where components move progressively through a series of workstations. Each station handles a specific task—like drilling, riveting, bonding, or inspection—with the goal of achieving consistent quality and faster build times.

Unlike traditional manufacturing setups where parts may bounce between departments, aerospace flow lines are highly organized. Everything moves in a controlled sequence, much like an assembly line, but with aerospace-level complexity and precision.

Why Flow Lines Matter in Aerospace

Aerospace parts aren’t just big—they’re incredibly intricate. Tolerances are tight. Materials are specialized. And one small mistake can cost thousands. That’s why flow lines are so valuable. They:

-

Minimize human error

-

Speed up production timelines

-

Improve quality control

-

Enable repeatable, scalable builds

-

Reduce unnecessary movement and handling

For large fuselage sections or wing assemblies, a flow line approach turns chaos into consistency.

1. Planning Your Aerospace Flow Line

Every good system starts with solid planning. Before you install anything, you need a clear understanding of your product, your production goals, and your current bottlenecks.

Ask yourself:

-

What’s your current takt time?

-

Where are you losing efficiency?

-

Which processes are most labor-intensive?

-

Do you have space constraints?

Once you know the answers, you can start designing a flow that matches your needs and delivers real results.

2. Tailoring the Design to Your Product

Not all aerospace flow lines look the same—and they shouldn’t. A line for a composite wing skin will look very different from one handling aluminum frame sections or engine nacelles.

You’ll want to design your line based on:

-

Part geometry and size

-

Material handling requirements

-

Assembly steps

-

Quality control needs

-

Automation vs. manual labor balance

Customization is key. Trying to force a generic line into a high-precision aerospace environment just doesn’t work.

3. Integrating Automation and Robotics

These days, automation plays a major role in flow line efficiency. From robotic drilling systems to automated guided vehicles (AGVs) moving components, there’s no shortage of smart tech to integrate into your line.

Automation not only speeds up cycle times but also improves safety and repeatability. And when you match that with human oversight at critical stages, you get the best of both worlds.

If you’re looking for advanced solutions to automate specific steps, this automation services page breaks down what’s available for aerospace manufacturers.

4. Ergonomics and Worker Safety

While flow lines aim to reduce labor intensity, there’s still a human element involved. That means designing for ergonomic safety is essential. Adjustable workstations, lifting assists, and easy access to tools all help reduce strain and injuries.

You want your line to not just be fast—but also sustainable for your team.

5. Material Flow and Logistics

You can’t build a flow line without thinking about material movement. Raw materials, subassemblies, and finished parts need to move in and out of the line efficiently. This involves:

-

Defining input/output stations

-

Using conveyors, dollies, or AGVs

-

Managing space for inventory

-

Ensuring traceability of parts

Efficient logistics keep everything running smoothly and prevent backups that can kill productivity.

6. Quality Control Integration

This is where aerospace flow lines shine. Quality can’t be an afterthought—it must be embedded into the line. That means placing inspection tools, sensors, and testing stations throughout the build.

Visual inspection cameras, CMM arms, ultrasonic scanners—all of these can be built into your line to catch issues before they become expensive mistakes.

7. Digital Twin and Simulation Tools

Before a single wrench turns, simulate your flow line using digital twin technology. These 3D models let you test everything—from timing and motion to layout and material flow—without physically building anything.

It’s a huge cost-saver and gives you the ability to make adjustments before go-live.

8. Flow Line Installation and Commissioning

When it’s time to put the plan into action, installation is everything. From anchoring machinery to running power and data lines, your install crew needs to follow strict protocols.

Commissioning includes:

-

Validating all mechanical/electrical systems

-

Running test cycles

-

Training operators and maintenance teams

-

Troubleshooting and refining processes

This phase ensures the line is fully functional and ready to deliver consistent output.

9. Ongoing Optimization and Upgrades

Even after your aerospace flow line is up and running, it’s not “set it and forget it.” Continuous improvement is part of the game. Track KPIs, watch for inefficiencies, and look for opportunities to automate more steps or simplify tasks.

The best flow lines evolve over time.

10. Choosing the Right Partner

Designing and implementing aerospace flow lines is no small task. You need a team that understands the strict tolerances, heavy materials, and safety standards that come with aerospace production.

Look for partners who offer:

-

End-to-end design and engineering support

-

Custom tooling and automation experience

-

Deep aerospace industry knowledge

-

Proven success stories

If you’re serious about getting it right the first time, working with experts in aerospace flow lines can make all the difference.

Final Thoughts

The aerospace industry is high-stakes—and your production systems need to rise to the challenge. Well-designed flow lines not only increase output but also reduce errors, improve quality, and empower your team to deliver precision products on schedule.

From layout and logistics to automation and inspection, every piece of your flow line matters. Start with a clear plan, work with experienced pros, and stay focused on efficiency and quality.

If you’re ready to take your aerospace operations to the next level, explore tailored aerospace flow lines that can help you streamline assembly, improve traceability, and boost performance where it counts.

- Aerospace Flow Lines Explained: From Design to Implementation

- Learn how aerospace flow lines are designed, developed, and implemented to streamline aircraft manufacturing and improve efficiency from concept to completion.

- Aerospace Flow Lines

Related posts:

Luxury or Budget? Finding the Right Heathrow Transfer for You

Luxury or Budget? Finding the Right Heathrow Transfer for You

What Is Cold Rolled Stainless Steel Coil and Why Does It Matter?

What Is Cold Rolled Stainless Steel Coil and Why Does It Matter?

Make Impact with Commercial Signs Raleigh NC: A Strategic Guide to Business Success

Make Impact with Commercial Signs Raleigh NC: A Strategic Guide to Business Success

PEX vs Copper in New Homes: What’s Right for You? | Creative Repipe

PEX vs Copper in New Homes: What’s Right for You? | Creative Repipe

Top Benefits of Professional Roller Shutter Repair in London

Top Benefits of Professional Roller Shutter Repair in London

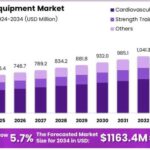

Aqua Gym Equipment Used in Holistic Wellness and Mind-Body Programs

Aqua Gym Equipment Used in Holistic Wellness and Mind-Body Programs

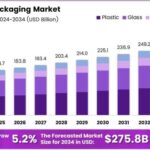

Transparency and Trust Through Beverage Packaging Supports Anti-Counterfeiting Measures

Transparency and Trust Through Beverage Packaging Supports Anti-Counterfeiting Measures

Key Time Management Strategies for Small Business Owners and Freelancers in 2025

Key Time Management Strategies for Small Business Owners and Freelancers in 2025