Introduction: Where Precision Meets Pressure

In the bustling heart of any commercial kitchen, time slices thinner than prosciutto. Speed must never compromise safety, and consistency is not a luxury—it’s the law. Meat slicers, once simple mechanical tools, have transformed into precise culinary instruments that underpin modern foodservice operations. In 2025, these machines are no longer just about slicing—they are about efficiency, hygiene, safety, and smart integration. Kitchens now demand more than durability—they demand devices that think, adapt, and perform.

for more inform : https://market.us/report/us-meat-slicer-market/

Adjustable Thickness Control: Tailoring Every Cut

No two cuts are the same, and in the high-stakes world of commercial food prep, adjustable thickness control is a slicer’s beating heart. Whether it’s translucent slices of prosciutto for an antipasto platter or hearty wedges of roast beef for deli sandwiches, chefs rely on precision down to the millimeter.

The latest slicers offer micro-dial adjustments with tactile feedback, allowing operators to tweak the thickness on the fly without restarting the machine. This isn’t just about aesthetic—it’s about portion control, cost-efficiency, and culinary integrity. Consistency in thickness equates to consistency in flavor, texture, and customer satisfaction.

Automatic Operation: Efficiency in Motion

Gone are the days when a line cook stood guard, manually feeding slabs of meat into a blade. Today’s commercial slicers boast fully or semi-automatic operation, allowing teams to multitask without compromising quality. With programmable slicing patterns and push-button start cycles, these machines slice through work hours like butter.

Not only does this technology reduce labor strain, but it also enhances throughput during peak service hours. With a rhythmic hum and precise repetition, automatic slicers keep production flowing—quietly, reliably, and with surgical consistency.

Built-in Sharpeners: Keeping the Edge Alive

In commercial kitchens, a dull blade isn’t just a nuisance—it’s a liability. That’s why top-tier slicers in 2025 come equipped with integrated sharpening systems that can be activated daily or on-demand. These built-in components restore blade keenness in minutes, minimizing downtime and extending the blade’s lifespan.

Operators can sharpen without removing the blade or halting kitchen operations, ensuring that every slice—whether it’s the first or the thousandth—meets the same standard. In high-volume environments, this feature isn’t a perk; it’s a production imperative.

Safety Enhancements: Protecting Hands and Reputations

In an industry where one accident can lead to both injury and liability, safety is paramount. Today’s commercial slicers incorporate multi-layered protection systems: blade guards, non-slip bases, dual-hand activation controls, and emergency stop switches.

Advanced models even feature automatic shut-off when idle or improperly used, and cut-resistant carriage designs that minimize contact with moving blades. These aren’t just safety features—they’re risk management tools, engineered to preserve both people and brand integrity.

Sanitation by Design: Cleanliness Meets Compliance

Health inspectors don’t care how fast a slicer is—they care how clean it stays. That’s why slicers in 2025 are built with sanitation in mind. Removable components, seamless stainless steel surfaces, and tool-free disassembly allow for fast, thorough cleaning between uses.

Many models now feature antimicrobial coatings and drip management systems, preventing buildup and cross-contamination. With FDA and NSF compliance baked into the design, these slicers don’t just clean easily—they clean legally.

Smart Slicer Technology: The Digital Edge

In an increasingly data-driven industry, slicers are becoming smart appliances. Embedded IoT chips and cloud-based software offer real-time analytics on usage rates, maintenance cycles, and blade performance. Some systems even integrate with kitchen management software, alerting staff when cleaning is due or parts need replacement.

Predictive maintenance minimizes surprise breakdowns, while digital dashboards optimize workflow. For multi-location chains, remote monitoring ensures that each unit performs at peak efficiency—no matter where it’s slicing.

for more inform : https://market.us/report/us-meat-slicer-market/

Conclusion: Engineered to Perform Under Pressure

In the demanding rhythm of commercial kitchens, a slicer must be more than sharp—it must be intelligent, hygienic, safe, and relentless. The features defining slicers in 2025 are born not just from innovation but from necessity. They reflect a culinary world that prizes precision, performance, and accountability.

These machines have evolved into indispensable kitchen allies—silent workhorses that slice not just meat, but time, waste, and error. As the foodservice industry continues to evolve, one thing is clear: only the sharpest

- Safety First: The Regulatory Side of the Meat Slicer Industry

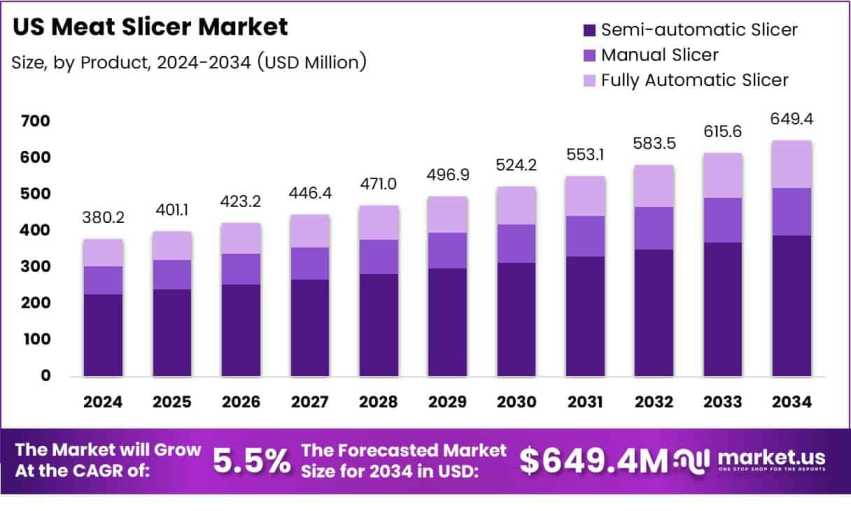

- Discover how the US meat slicer market is slicing through traditional boundaries with innovation, smart technology, and rising consumer demand. This in-depth article explores key market drivers,

- US Meat Slicer Market Kitchen Appliance Industry

Related posts:

Fitness for Mental Clarity: Unlock Your Focus and Inner Strength with DG FIT MIND

Fitness for Mental Clarity: Unlock Your Focus and Inner Strength with DG FIT MIND

Top Carrier Oil Suppliers in India for Bulk & Wholesale Buyers

Top Carrier Oil Suppliers in India for Bulk & Wholesale Buyers

Atlas Pro ONTV : La Révolution de la Télévision par Internet

Atlas Pro ONTV : La Révolution de la Télévision par Internet

Essentials Hoodie Design Philosophy: Minimalism Meets Statement

Essentials Hoodie Design Philosophy: Minimalism Meets Statement

Make Your Message Stick: The Power of Flyers & Posters in Plano!

Make Your Message Stick: The Power of Flyers & Posters in Plano!

Integrating Type form with High Level: A Comprehensive Guide

Integrating Type form with High Level: A Comprehensive Guide

What Solar Looks Like on Flat Roofs, Metal Roofs, and Shingles?

What Solar Looks Like on Flat Roofs, Metal Roofs, and Shingles?

When Best Stock Market Institute Delhi Becomes Your Turning Point Forever

When Best Stock Market Institute Delhi Becomes Your Turning Point Forever