The Rise of Carbon Fiber Bikes

From Innovation to Everyday Utility

Carbon fiber bikes, once reserved for professional pelotons and Olympic tracks, are now becoming a regular sight on city streets, mountain trails, and weekend group rides. Originally derived from aerospace materials, carbon fiber first made its mark in cycling during the 1980s and 1990s, promising unprecedented strength-to-weight advantages. Back then, the cost was astronomical and the technology too immature for mass-market appeal. Fast forward to today, and carbon fiber frames are no longer niche artifacts—they’re the benchmark of premium engineering and, increasingly, a practical choice for everyday riders. Improved manufacturing methods, globalized supply chains, and refined design practices have brought carbon bikes closer to the average consumer, transforming them from high-end luxury into aspirational necessity.

For more info visit : https://market.us/report/carbon-fiber-bike-market/

Consumer Trends Shaping the Market

Lightweight Obsession Meets Performance Demand

Riders of all skill levels are looking for one thing above all else: performance without compromise. The growing demand for lightweight bikes isn’t just about going faster—it’s about riding smarter. A lighter frame means improved handling, better acceleration, and reduced rider fatigue. Carbon fiber answers this call with precision. Its stiffness provides excellent power transfer, while its flexibility allows manufacturers to fine-tune ride comfort.

At the same time, consumers expect more than just a well-shaped frame. Modern buyers want integration—features like concealed cables, internal storage compartments, and compatibility with digital components such as GPS trackers, electronic shifting systems, and power meters. As bicycles evolve into smart machines, carbon fiber frames have become the perfect chassis to support this convergence of physical and digital performance.

Manufacturing Challenges and Material Realities

The High Cost of Going Light

Despite the market expansion, producing a carbon fiber bike remains a demanding endeavor. Unlike aluminum or steel frames that are easily shaped and welded, carbon fiber frames are constructed through intricate layup techniques, where sheets of fiber are layered by hand into molds. After curing in high-pressure ovens, the result is a stiff yet supple masterpiece—but one that demands skilled labor, time, and expensive machinery.

Raw material costs further complicate the equation. Polyacrylonitrile (PAN), the primary ingredient in most high-grade carbon fibers, is both expensive and energy-intensive to produce. Moreover, the global supply chain for carbon fiber components is concentrated in select regions, notably Taiwan and China. Any disruption—be it from geopolitics, pandemics, or shipping gridlocks—can send ripples through the entire industry. These vulnerabilities keep carbon bikes on the higher end of the price spectrum and pose serious barriers to scaling production without sacrificing quality.

For more info visit : https://market.us/report/carbon-fiber-bike-market/

Market Segmentation and Global Penetration

Premium Riders, Mid-Tier Converts, and Emerging Regions

The carbon fiber bike market reflects a diverse and segmented consumer base. High-end models, designed for elite cyclists, remain the face of innovation—offering ultra-light builds, aggressive geometries, and advanced aerodynamics. Yet, the real engine of growth is in the mid-range sector. These bikes balance carbon performance with reasonable pricing, targeting enthusiasts, commuters, and recreational riders.

Additionally, the global footprint of the market is expanding. Emerging regions such as Southeast Asia, Eastern Europe, and Latin America are seeing a rise in cycling culture, driven by urban congestion, rising fuel prices, and a push for healthier lifestyles. As local distributors and manufacturers step up, new market entry points are opening, making carbon bikes accessible to first-time buyers without diluting the brand equity of performance.

Sustainability and Future Roadmaps

Can Carbon Fiber Go Green?

As environmentally conscious consumers take center stage, the carbon fiber industry faces a significant conundrum: how to marry high performance with low ecological impact. Traditional carbon frames, once broken or retired, typically end up in landfills due to their non-recyclable thermoset construction. The energy-intensive production process only adds to their carbon footprint—ironically problematic for a mode of transport marketed as sustainable.

Nevertheless, the industry is exploring promising alternatives. Thermoplastic carbon composites, which can be reshaped and reused, are gaining traction. Modular frame designs that allow parts to be replaced instead of discarded are also emerging. Meanwhile, some brands are investing in closed-loop recycling and biodegradable resins. While these solutions are still in development, they signal a shift toward a circular economy model that could redefine what it means for a bike to be truly “green.”

Conclusion

The carbon fiber bike market is racing toward a bold and complex future. It’s an industry powered by innovation but challenged by cost, sustainability, and accessibility. As the global appetite for high-performance, lightweight bicycles continues to rise, the path forward will be shaped not just by material science but also by economic pragmatism and environmental responsibility. The winners of this race won’t just be the fastest—but the most adaptable.

- Carbon Fiber Bikes Drive Global Market with Innovation and Demand

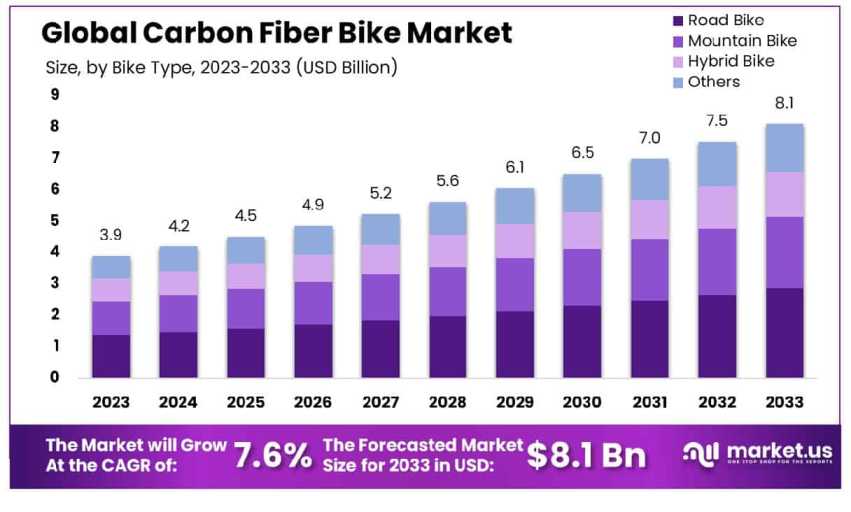

- The carbon fiber bike market is evolving rapidly, driven by demand for lightweight performance, technological innovation, and expanding global accessibility. As sustainability and supply chain resilience gain focus, the market promises strong and strategic growth.

- carbonfiberbikes, bikemarketanalysis

Related posts:

Finding the Right MOT Centre Near Me: Why NH Service Center Ltd Is Milton Keynes’ Trusted Choice

Finding the Right MOT Centre Near Me: Why NH Service Center Ltd Is Milton Keynes’ Trusted Choice

Why More UK Drivers Are Switching to Japanese Used Cars with Nobuko Japan

Why More UK Drivers Are Switching to Japanese Used Cars with Nobuko Japan

Electric Skateboards: Revolutionizing Urban Travel and Commuting

Electric Skateboards: Revolutionizing Urban Travel and Commuting

Importance of Employee Training and Certification in Service Quality Assurance

Importance of Employee Training and Certification in Service Quality Assurance

From Basic Service to Complex Repairs: One Trusted Garage for Your German Car in Abu Dhabi

From Basic Service to Complex Repairs: One Trusted Garage for Your German Car in Abu Dhabi

Why the VW Beetle Engine Model Kit is a Must-Have for Automotive Hobbyists

Why the VW Beetle Engine Model Kit is a Must-Have for Automotive Hobbyists

Unlock Your Potential with Unichrone’s Attention Management Certification

Unlock Your Potential with Unichrone’s Attention Management Certification

American Muscle: Ford Mustang vs. Chevrolet Camaro vs. Dodge Challenger

American Muscle: Ford Mustang vs. Chevrolet Camaro vs. Dodge Challenger