Introduction

In the vast expanse of the global maritime industry, ships are more than mere vessels they are dynamic ecosystems that require continual care to operate efficiently. Ship repair and maintenance are not auxiliary tasks but essential functions that preserve the seaworthiness, compliance, and economic viability of every marine asset. Without timely intervention and consistent upkeep, even the most robust ships risk mechanical obsolescence or catastrophic failure. The stakes are monumental, not just financially, but environmentally and humanly.

For more info please visit: https://market.us/report/ship-repair-and-maintenance-service-market/

Understanding the Scope of Ship Maintenance

Planned vs. Unplanned Maintenance

Planned maintenance encompasses scheduled inspections, replacements, and overhauls—an orchestrated symphony of tasks based on time or usage metrics. This is the backbone of reliability-centered maintenance strategies. Unplanned maintenance, on the other hand, strikes unpredictably—often at sea or in port—demanding swift triage and remediation. The distinction is critical: while planned upkeep preserves, unplanned repairs restore. The cost, complexity, and consequences of each are vastly different.

Class Requirements and Regulatory Framework

Shipping is a tightly regulated industry governed by classification societies like Lloyd’s Register, DNV, and ABS. These entities enforce standards on structural integrity, propulsion systems, and onboard safety protocols. Beyond that, international regulations such as SOLAS (Safety of Life at Sea) and MARPOL (Marine Pollution) dictate rigorous maintenance schedules and documentation. Non-compliance is not just a bureaucratic misstep—it’s a threat to crew safety, cargo integrity, and environmental stewardship.

Types of Ship Repairs

Hull and Structural Repairs

The hull endures ceaseless punishment—from turbulent waters to corrosive salt sprays. Structural repairs involve weld renewals, plate replacements, and rust mitigation. In severe cases, entire sections of the hull may be re-fabricated. Ultrasonic testing, radiography, and hydrostatic pressure testing ensure that repairs restore not just form, but function.

Engine and Mechanical Overhauls

Ship engines colossal, intricate, and vital require meticulous overhauls. These range from cylinder liner honing and crankshaft alignment to turbocharger replacement and fuel injector calibration. Often, propulsion systems must be disassembled and rebuilt with microscopic precision. The stakes are high: a single misaligned bearing can precipitate catastrophic failure.

Electrical and Electronic Systems Repair

Modern vessels are digitally intricate. Navigation, communication, and automation rely on a web of sensors, wiring, and microcontrollers. Repairs here might involve rewiring switchboards, recalibrating radar arrays, or replacing PLC modules. Electrical faults can be elusive—intermittent, latent, or triggered by environmental stressors like humidity and salt.

Dry Docking and Underwater Maintenance

Dry docking allows ships to be hoisted above water for a complete keel-to-mast inspection. Hull cleaning, antifouling paint application, rudder repair, and propeller polishing are typical procedures. Conversely, underwater maintenance, conducted by saturation divers or ROVs (Remotely Operated Vehicles), involves patch welding, anode replacement, and hull inspections without removing the vessel from water.

Technological Advancements in Ship Repair

Use of Robotics and Automation

Drones and robotic crawlers now inspect cargo holds, ballast tanks, and confined spaces. Automated welders and AI-powered diagnostics reduce human exposure to hazardous zones while increasing repair accuracy. Robotics has shifted the paradigm from labor-intensive to tech-assisted repair environments, enabling 24/7 operability.

Predictive Maintenance and IoT Integration

Predictive analytics, powered by onboard sensors and cloud-based algorithms, can forecast failures before they manifest. Internet of Things (IoT) systems monitor temperature, vibration, oil viscosity, and electrical loads in real-time. These tools don’t just detect—they predict, creating a proactive repair culture rather than reactive firefighting.

Global Ship Repair Hubs and Market Dynamics

Strategic Locations and Their Significance

Ports in Singapore, Dubai, Rotterdam, and Busan have evolved into repair epicenters due to their strategic proximity to major shipping routes. These hubs offer dry dock facilities, skilled labor pools, and regulatory compliance services. Location is not merely geographic it’s strategic.

Labor, Cost, and Environmental Regulations

Repair costs hinge on labor rates, availability of materials, and environmental policies. European yards may offer high-tech services but at premium prices, whereas Southeast Asian yards balance affordability with growing sophistication. Environmental regulations now compel yards to adopt eco-friendly practices wastewater treatment, emissions control, and low-toxicity coatings.

For more info please visit: https://market.us/report/ship-repair-and-maintenance-service-market/

Challenges and Future Prospects

Sustainability and Green Repair Practices

As carbon neutrality becomes non-negotiable, repair practices are being re-engineered for sustainability. Bio-based antifoulants, recyclable materials, and hybrid engine retrofits are gaining traction. The challenge lies in retrofitting aging vessels with minimal disruption and maximum benefit.

Workforce Shortages and Skills Gap

The maritime sector faces an acute shortage of skilled repair technicians. Welding, marine electrical systems, and diagnostics are high-demand yet understaffed domains. Upskilling initiatives, technical apprenticeships, and cross-industry collaborations are crucial to plug this expertise gap.

The Shift Towards Digital Shipyards

Digital shipyards integrate ERP systems, digital twins, and cloud-based coordination platforms to streamline repair cycles. From 3D modeling of repairs to real-time progress tracking, these smart yards reduce downtime and enhance transparency. This is not a trend it’s the future architecture of ship maintenance.

Conclusion

Ship repair and maintenance remain pivotal to global commerce and maritime safety. With evolving technologies, stricter regulations, and mounting environmental concerns, the industry is at an inflection point. To stay afloat—literally and metaphorically—stakeholders must embrace innovation, strategic collaboration, and sustainable practices. The sea may be eternal, but the vessels that sail it require relentless care.

- From Hull to Engine: A Deep Dive into Modern Ship Maintenance Methods

- Explore the essential practices and innovations in ship repair and maintenance that keep global maritime operations running smoothly. From dry docking to predictive diagnostics, discover how the industry is evolving to meet modern challenges and ensure fleet reliability.

- #ShipMaintenance #MaritimeIndustry #ShipRepair #MarineEngineering #DryDocking #FleetManagement #PredictiveMaintenance #MaritimeTechnology #VesselMaintenance #OceanLogistics #SmartShipping #SustainableShipping #ShipyardOperations #NavalArchitecture #MarineInnovation

Related posts:

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Law Notes PDF Download: A Smart Resource for Law Students and Aspirants

Law Notes PDF Download: A Smart Resource for Law Students and Aspirants

A Section 8 Company Registration Process with the ngoexperts

A Section 8 Company Registration Process with the ngoexperts

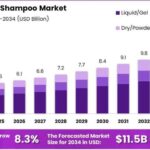

Why the World Is Going Sulfate-Free—One Shampoo Bottle at a Time

Why the World Is Going Sulfate-Free—One Shampoo Bottle at a Time

The mystery to great connections? Acknowledge family and companions for who they truly are

The mystery to great connections? Acknowledge family and companions for who they truly are

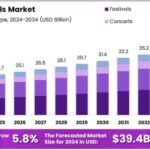

Alpaca Apparel Market on the Rise: Sustainability Meets Sophistication

Alpaca Apparel Market on the Rise: Sustainability Meets Sophistication

Pop-up Hotels Go Luxe: The Intersection of Glamour and Nature

Pop-up Hotels Go Luxe: The Intersection of Glamour and Nature

Master Financial Markets with ICFM’s Trusted Trading and Investment Certification in India

Master Financial Markets with ICFM’s Trusted Trading and Investment Certification in India