In a world increasingly focused on sustainability, efficiency, and clean technologies, hollow fiber ceramic membranes are emerging as a game-changer in the global filtration industry. These advanced membranes, known for their robust structure, chemical resistance, and exceptional thermal stability, are revolutionizing filtration processes across water treatment, biotechnology, food & beverage, chemical processing, and oil & gas sectors.

The Hollow Fiber Ceramic Membrane Market is gaining momentum due to rising demand for ultrafiltration and microfiltration solutions that can withstand extreme operating environments and aggressive chemicals—something polymeric membranes often fail to deliver.

Get More Details: https://www.databridgemarketresearch.com/reports/global-hollow-fiber-ceramic-membrane-market

What Are Hollow Fiber Ceramic Membranes?

Hollow fiber ceramic membranes are porous, tubular filtration structures made from high-performance ceramic materials such as alumina, zirconia, and titania. They feature hollow fibers with fine pore sizes, enabling efficient separation of particles, microorganisms, and organic molecules from liquids or gases.

Key Features:

-

Superior Chemical & Thermal Resistance

-

Long Lifespan & Reusability

-

Low Fouling Tendency

-

Easy Backflushing & Cleaning

-

Stable Filtration Under High Pressure and Temperature

Market Overview

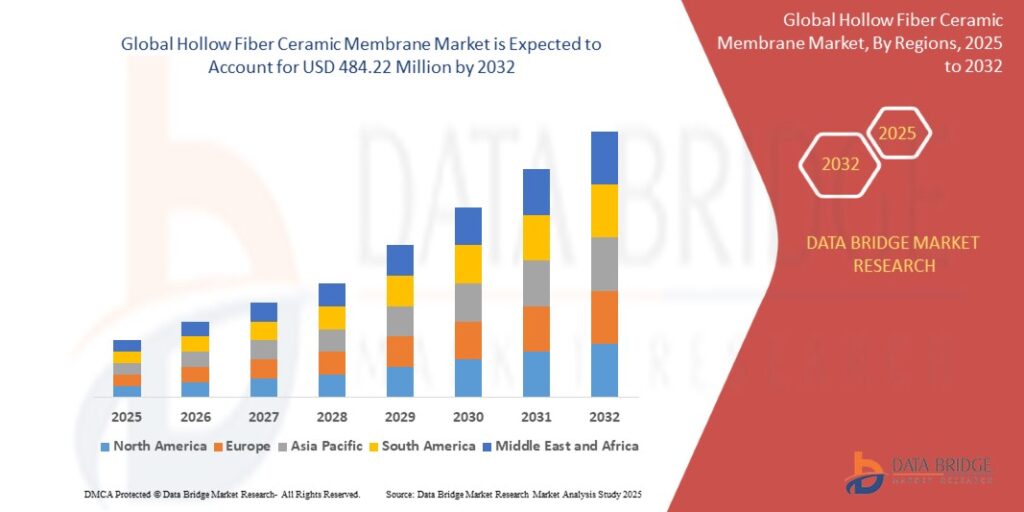

The global hollow fiber ceramic membrane market was valued at approximately USD 300 million in 2023 and is expected to reach USD 750 million by 2030, growing at a CAGR of 14%. This growth is driven by increased industrial filtration demand, strict environmental regulations, and the push for sustainable water management practices.

Key Market Drivers

💧 Rising Demand for Water and Wastewater Treatment

-

Urbanization and industrialization have intensified the need for durable and efficient membrane technologies in desalination, recycling, and wastewater reuse.

🏭 Industrial Process Optimization

-

Hollow fiber ceramic membranes provide cost-effective and consistent filtration in the chemical, pharmaceutical, and food industries, minimizing downtime and maintenance costs.

♻ Regulatory Push for Cleaner Production

-

Environmental policies worldwide are enforcing effluent discharge limits, spurring demand for advanced membrane filtration in process industries.

🔬 Biotechnology and Life Sciences Applications

-

Used for sterile filtration, protein separation, and cell harvesting, thanks to their ability to handle complex biological fluids under sterile conditions.

Applications of Hollow Fiber Ceramic Membranes

1. Water & Wastewater Treatment

-

Filtration of municipal, industrial, and greywater streams.

-

Removal of suspended solids, bacteria, and organic pollutants.

2. Food & Beverage Industry

-

Clarification and concentration of fruit juices, dairy products, and wine.

-

Retention of flavor compounds while removing impurities.

3. Pharmaceutical & Biotech

-

Cell culture processing, enzyme recovery, and purification of biopharmaceuticals.

-

Sterile filtration for injectable drugs and lab processes.

4. Chemical & Petrochemical Sector

-

Recovery of solvents, catalysts, and valuable chemicals.

-

Filtration of corrosive and high-temperature liquids.

5. Oil & Gas

-

Treatment of produced water, removal of hydrocarbons and particulates.

-

Use in downstream refining and enhanced oil recovery.

Challenges in the Hollow Fiber Ceramic Membrane Market

⚠ High Initial Cost – Compared to polymeric alternatives, ceramic membranes involve higher capital expenditure.

⚠ Complex Manufacturing Process – Production of hollow fiber ceramics requires precision sintering, shaping, and sealing, increasing costs.

⚠ Limited Awareness & Adoption – In developing markets, the lack of technical knowledge and upfront cost barriers hinder growth.

Future Trends and Innovations

🌱 Integration with Green Technologies

-

Membranes used in zero-liquid discharge (ZLD) systems, bioenergy production, and carbon capture applications.

🧠 Smart Membrane Systems

-

IoT-enabled modules for real-time monitoring, predictive maintenance, and process optimization.

🔄 Hybrid Membrane Systems

-

Coupling ceramic membranes with UV, ozone, or biological treatment for superior contaminant removal.

🧪 Material Science Breakthroughs

-

Development of nanoparticle-enhanced and graphene-based ceramic membranes to improve flux, fouling resistance, and selectivity.

Leading Players in the Market

-

METAWATER Co., Ltd.

-

Atech Innovations GmbH

-

Nanostone Water Inc.

-

Ceraflo Pte Ltd.

-

LiqTech International, Inc.

-

Mantec Technical Ceramics Ltd.

These companies are heavily investing in R&D, product customization, and strategic partnerships to expand their market presence globally.

Regional Insights

Asia-Pacific

-

Fastest-growing region, driven by urbanization, water scarcity, and industrial expansion, especially in China and India.

North America

-

High adoption in biotechnology, water reuse, and chemical industries, supported by strong regulatory frameworks.

Europe

-

Focus on circular economy, sustainable wastewater solutions, and food safety is boosting demand.

Middle East & Africa

-

Rising need for desalination and water recycling in arid regions opens opportunities for ceramic membrane technologies.

Conclusion

The Hollow Fiber Ceramic Membrane Market stands at the intersection of sustainability, innovation, and industrial efficiency. With their unmatched durability, low fouling characteristics, and compatibility with harsh environments, ceramic membranes are reshaping how industries treat and reuse water, manage waste, and optimize production.

As technology advances, costs decline, and environmental regulations tighten, the future of hollow fiber ceramic membranes looks not only promising but pivotal to a cleaner, more resource-efficient world.

FAQs

1. What makes hollow fiber ceramic membranes different from polymeric membranes?

They are made from inorganic materials like alumina or zirconia, offering higher thermal, chemical, and mechanical resistance, making them suitable for harsh operating conditions.

2. What are the primary applications of these membranes?

They are used in wastewater treatment, food and beverage clarification, biotech processing, chemical recovery, and oil-water separation.

3. Why are ceramic membranes preferred for industrial use?

Because of their long service life, high flux rates, chemical resistance, and minimal fouling, they provide greater long-term value and lower total cost of ownership.

4. Are ceramic membranes environmentally friendly?

Yes, they enable water recycling, reduce chemical usage, and contribute to zero-discharge industrial operations, supporting sustainable development.

5. What is the future of hollow fiber ceramic membranes?

The future involves smarter, more efficient systems, integration with green technologies, and material innovations that will expand their reach across emerging and developed economies.

- Global Hollow Fiber Ceramic Membrane Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2032

- Global Hollow Fiber Ceramic Membrane Market Segmentation, By Application (Ultrafiltration, Microfiltration, and Nanofiltration), End-use (Biotechnology, Chemical Processing, Water & Wastewater Processing, Pharmaceutical, Food & Beverages, and Others) – Industry Trends and Forecast to 2032

- Hollow Fiber Ceramic Membrane Market Size, Hollow Fiber Ceramic Membrane Market Share, Hollow Fiber Ceramic Membrane Market Trend, Hollow Fiber Ceramic Membrane Market Growth

Related posts:

How UAE Fitout Experts Are Elevating Luxury Brand Spaces in 2025

How UAE Fitout Experts Are Elevating Luxury Brand Spaces in 2025

Sp5der Hoodie: Comfort, Fit, and Real-World Functionality Redefined

Sp5der Hoodie: Comfort, Fit, and Real-World Functionality Redefined

Discover the Best Full Body Massage Experience in Lancaster, PA with Focused Care Therapeutic Massage

Discover the Best Full Body Massage Experience in Lancaster, PA with Focused Care Therapeutic Massage

ISO 27001 Training: A Real-World Lifeline to Reduce the Risk of Data Breaches

ISO 27001 Training: A Real-World Lifeline to Reduce the Risk of Data Breaches

How Instagram Stories Help Businesses: A 2025 gerat Guide ..

How Instagram Stories Help Businesses: A 2025 gerat Guide ..

“GV GALLERY® || TheGv Gallery Shop || Official Clothing Store “

“GV GALLERY® || TheGv Gallery Shop || Official Clothing Store “

Don’t Miss Out on today’s Best Sale Offer with Huge Discounts!

Don’t Miss Out on today’s Best Sale Offer with Huge Discounts!

CPT vs ICD-10 Codes: What Every Medical Biller Needs to Know

CPT vs ICD-10 Codes: What Every Medical Biller Needs to Know