When it comes to construction or renovation projects, scaffolding plays a vital role in ensuring both safety and efficiency. But with multiple options available, you may wonder how System Scaffolding in Corby stands apart from traditional tube and fitting scaffolding. This blog dives into the key differences between these two popular methods, explaining why System Scaffolding is becoming the go-to choice for many projects in Corby.

Whether you’re an experienced contractor or simply curious about modern scaffolding methods, this guide will explore the advantages, limitations, and situations where each type excels, helping you make well-informed decisions.

What Is System Scaffolding in Corby?

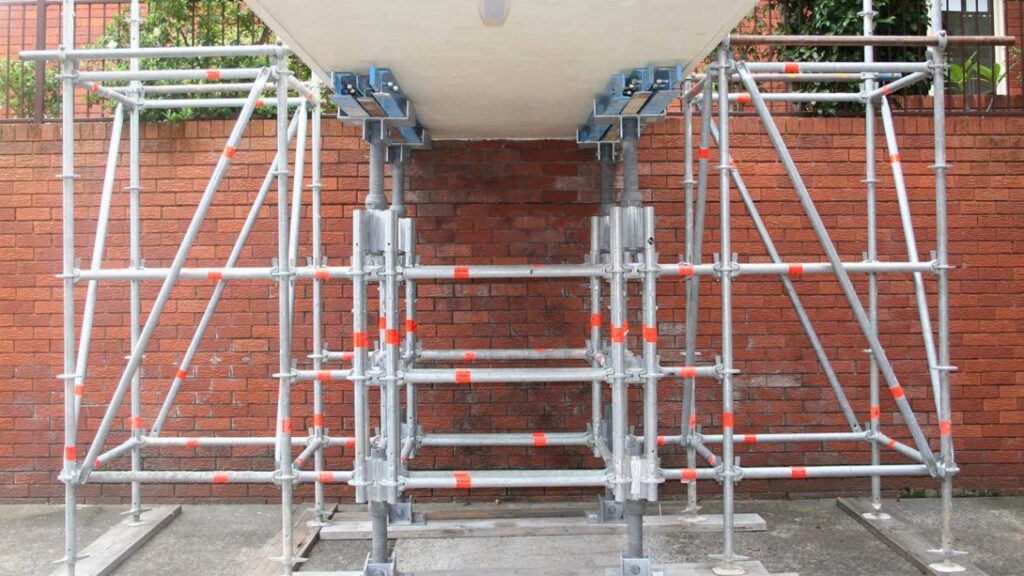

System Scaffolding refers to a pre-engineered scaffolding framework that consists of modular components designed to lock into place easily. Commonly found on construction sites across Corby, it is admired for its speed, precision, and adaptability. Scaffolder Corby, a trusted name in scaffolding services, frequently employs this method because of its remarkable efficiency.

Unlike tube and fitting scaffolding, which requires assembling every piece manually, System Scaffolding uses standardised, factory-produced parts. This design not only minimises the labour time but also reduces the risk of errors. Whether used for a small-scale refurbishment or a large construction project in Corby, this option ensures a reliable and robust framework.

By adopting an advanced design, System Scaffolding reduces complexities that may occur with traditional methods. If safety and speed are high on your priority list, this modern solution might be ideal.

Key Differences Between System Scaffolding and Tube and Fitting

Structure and Assembly

System Scaffolding in Corby stands out primarily due to its modular setup. With pre-measured components, workers can easily piece the framework together, saving time and effort. Usually built using a combination of vertical standards, horizontal ledgers, and diagonal braces, it allows for quick assembly, even on large-scale projects.

On the other hand, tube and fitting scaffolding relies heavily on manual construction. Each tube is individually fitted and held together using couplers, which allows for greater flexibility in design. However, this flexibility comes at the cost of increased labour time and a steeper learning curve for workers who are less experienced. Depending on the complexity of the project, traditional scaffolding may require additional team members, subsequently increasing costs.

Customisability and Versatility

When it comes to complex projects that involve irregular shapes or non-standard structures, tube and fitting scaffolding is often preferred due to its near-unlimited customisability. With fewer restrictions imposed by pre-designed parts, it can handle challenging configurations with ease. For historical or bespoke construction in Corby, this may still be a practical option.

However, System Scaffolding in Corby is not without its strengths. Its components come in various lengths and angles, allowing it to work well in many modern settings. For straightforward applications such as housing developments, industrial buildings, or public infrastructure projects, its cutting-edge design often proves sufficient.

Efficiency and Cost Considerations

Labour Efficiency

Time is a key factor to consider when comparing these methods. System Scaffolding provides a much faster setup process thanks to its pre-engineered parts. Scaffolding services such as Scaffolder Corby value this speed, which not only accelerates project timelines but also minimises labour-related expenses.

Tube and fitting scaffolding, while versatile, is significantly more time-intensive due to the manual assembly involved. Each connection point has to be individually secured, which can extend the setup time by hours or even days. For projects operating on tight deadlines in Corby, this might not be the most practical option.

Budget Implications

System Scaffolding may feature higher initial costs due to its engineered nature, but the reduction in labour time often balances these expenses. Additionally, fewer mistakes during assembly mean you’re less likely to encounter delays or incur repair-related costs.

Alternatively, tube and fitting scaffolding offers lower upfront costs but can become costly over time due to increased labour demands. While it might suit smaller projects with flexible deadlines, its overall cost-efficiency may diminish for larger-scale ventures.

Safety Standards and Reliability

Safety cannot be compromised in any scaffolding operation. System Scaffolding in Corby is designed with safety at its core; pre-engineered components meet rigorous industry standards to ensure structural stability. This feature reduces the likelihood of slips or disassemblies, keeping workers and bystanders safe.

Tube and fitting scaffolding, while reliable, requires a high level of technical skill during assembly. Improper construction can lead to weak points that compromise the system’s integrity. For this reason, experienced scaffolding professionals like Scaffolder Corby are essential when opting for this traditional method.

Environmental Impact

System Scaffolding is often seen as the more sustainable option due to its reusability and precision manufacturing. Minimal material waste occurs during assembly, and the durable components are suitable for years of repeated use. Since it reduces the need for overstock materials, it aligns well with the growing demand for environmentally conscious construction practices in Corby.

While tube and fitting scaffolding also supports reuse, the manual cutting and shaping of tubes can result in higher waste levels, especially for non-standard designs. For eco-conscious project managers, this may present an additional challenge.

When to Choose System Scaffolding in Corby?

For straightforward, modern projects that prioritise efficiency and safety, System Scaffolding is a natural fit. Housing developments, commercial buildings, and large-scale ventures in Corby greatly benefit from its quick assembly, reliability, and cost-effectiveness. With expert providers like Scaffolder Corby, adopting this method ensures your project stays on track.

However, traditional tube and fitting scaffolding still has its place in the construction landscape. Projects requiring hyper-specific customisation or dealing with historical structures might find its flexibility indispensable. The choice truly depends on the unique requirements of your undertaking.

Final Thoughts

Understanding the differences between System Scaffolding in Corby and traditional tube and fitting scaffolding lets you choose the right framework for your construction needs. By prioritising safety, efficiency, and cost-management, System Scaffolding has emerged as a highly practical, modern solution for many construction projects.

Whether you’re planning a simple renovation or tackling a complex architectural structure, knowing the strengths and limitations of each method empowers you to make informed decisions. For professional assistance, reach out to experts like Scaffolder Corby, who can guide you through the process and ensure your scaffolding system meets your project’s needs.

Selecting the right scaffolding could be the key to completing your project safely, on time, and within budget.

- How Is System Scaffolding in Corby Different from Tube and Fitting?

- Discover how System Scaffolding in Corby differs from tube and fitting scaffolding. Learn about efficiency, safety, and the best-fit solution for your project.

- System Scaffolding in Corby

Related posts:

Nelson Builders: Your Trusted Partner for Renovations and New Homes in Nelson

Nelson Builders: Your Trusted Partner for Renovations and New Homes in Nelson

Professional Cleaning Services in Malibu, CA – MLS Roofing & Construction

Professional Cleaning Services in Malibu, CA – MLS Roofing & Construction

Reliable Roof Installation in Waterford, CT | Brennan Roofing

Reliable Roof Installation in Waterford, CT | Brennan Roofing

When Is a Contractor License and Bond Legally Required: Hiring Tips

When Is a Contractor License and Bond Legally Required: Hiring Tips

ENVO Solutions LLC – Comprehensive Insulation & Building Envelope Systems for Maximum Efficiency

ENVO Solutions LLC – Comprehensive Insulation & Building Envelope Systems for Maximum Efficiency

Top 5 Interior Painting: Tips for a Fresh and Modern Home Look

Top 5 Interior Painting: Tips for a Fresh and Modern Home Look

Why Modular Kitchens Are the Smartest Choice for Modern Homes

Why Modular Kitchens Are the Smartest Choice for Modern Homes

How to Use a Muramatsu Flute Serial Number Lookup to Identify Your Model

How to Use a Muramatsu Flute Serial Number Lookup to Identify Your Model