In today’s fast-paced construction and electrical industries, reliability and efficiency are critical. One essential component that often plays a behind-the-scenes role in the smooth operation of electrical installations is AFC Cable Systems. Whether you’re working on residential, commercial, or industrial projects, AFC Cable Systems offers a versatile and secure solution for electrical wiring. However, like any system, efficient usage and proper maintenance are key to long-term performance and safety.

In this guide, we’ll explore everything you need to know about using and maintaining AFC Cable Systems efficiently—from installation best practices to troubleshooting and long-term care tips.

What Are AFC Cable Systems?

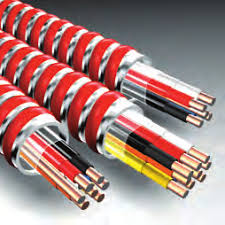

AFC Cable Systems refer to armored and flexible electrical conduit systems designed for the safe and organized routing of electrical wiring. Developed by AFC Cable Systems, Inc., these products include armored cable (AC), metal-clad cable (MC), flexible metal conduit (FMC), and various pre-wired cable solutions. Known for their durability, flexibility, and ease of installation, these cable systems are widely used across multiple industries.

Their primary role is to protect electrical conductors and make installations faster, safer, and more cost-effective. Whether you’re an electrician, contractor, or facilities manager, understanding how to use these systems correctly can enhance project outcomes.

Benefits of Using AFC Cable Systems

Before diving into maintenance and usage, it’s important to understand why AFC Cable Systems are preferred by many professionals:

-

Flexibility: Ideal for tight spaces and curved paths where rigid conduits are difficult to install.

-

Durability: Built to withstand moisture, vibration, and mechanical stress.

-

Time-saving: Pre-wired systems reduce labor and installation time.

-

Code Compliance: Designed to meet national and local electrical code requirements.

-

Versatility: Suitable for a wide range of environments, including commercial buildings, hospitals, schools, and industrial facilities.

Best Practices for Installing AFC Cable Systems

Proper installation is the first step toward ensuring the efficiency and longevity of any AFC cable system. Follow these best practices for optimal results:

1. Plan Your Route

Before installing AFC Cable Systems, map out your cable paths carefully. Avoid sharp bends or tight corners that can compromise the cable’s structure.

2. Use Correct Connectors and Fittings

Ensure you use manufacturer-recommended fittings for securing cables. These components maintain the integrity of the system and prevent issues like grounding faults or connection failure.

3. Secure Cables at Proper Intervals

Support the cables at intervals specified by the National Electrical Code (NEC) or local regulations. Overstretched or unsupported cables can sag or get damaged over time.

4. Avoid Moisture Exposure

Even though many AFC Cable Systems are rated for damp or wet environments, it’s best to avoid prolonged exposure unless you’re using cable specifically designed for such conditions.

5. Check for Damage Before Installation

Always inspect the cable for visible damage before installation. Dents, kinks, or broken armor can compromise performance and safety.

Tips for Efficient Usage of AFC Cable Systems

Once installed, efficient use of AFC Cable Systems depends on how well you manage them during operations. Here are some key tips to keep your system running smoothly:

1. Label and Organize

Label your cables during installation to simplify future maintenance. Use color-coded tags or labels to distinguish circuits, phases, and destinations.

2. Avoid Overloading

Each type of AFC cable has a rated ampacity. Make sure you’re not overloading circuits, which can cause overheating and reduce the life span of the cable.

3. Regularly Review Cable Layouts

Especially in industrial settings, it’s important to periodically review the cable layouts. This helps identify areas where adjustments may be needed due to equipment changes or operational growth.

4. Use Compatible Accessories

Ensure any additions to your AFC Cable Systems (such as junction boxes or extension fittings) are compatible and rated for use with the same type of cable.

How to Maintain AFC Cable Systems

Maintaining your AFC Cable Systems is crucial for both safety and performance. Here’s how to ensure they stay in good condition over the long term:

1. Routine Visual Inspections

Conduct routine visual inspections to check for wear, corrosion, or mechanical damage. Pay close attention to bends, joints, and connection points.

2. Test for Ground Continuity

Use a continuity tester to ensure proper grounding. AFC systems often rely on the armor for grounding, so integrity is vital.

3. Check for Moisture or Corrosion

In humid or wet environments, inspect for signs of corrosion, particularly around connectors and fittings. Replace any damaged components immediately.

4. Look for Heat Damage

Overloaded or poorly ventilated cables can generate heat, which may cause insulation breakdown. Watch for discoloration or melting and correct the root cause promptly.

5. Maintain Clean Surroundings

Keep areas around the cables clean and free from chemicals, dust, or other contaminants that might damage the cable sheath or armor.

Troubleshooting Common Issues

Even well-installed systems can occasionally develop issues. Here are some common AFC cable problems and how to fix them:

Problem: Loose Connections

Solution: Check the connectors and tighten or replace them as needed. Ensure you’re using the correct size and type of fittings.

Problem: Grounding Failures

Solution: Inspect grounding paths and test continuity. Replace damaged armor or upgrade connectors if needed.

Problem: Cable Overheating

Solution: Assess the load on the cable. Redistribute or reduce the electrical load to avoid exceeding ampacity.

Problem: Moisture Intrusion

Solution: Inspect the source of moisture. Replace damaged cables and improve environmental protection such as sealing conduits or installing protective covers.

When to Replace AFC Cable Systems

While AFC Cable Systems are built to last, they are not immune to wear and environmental damage. You should consider replacing them if:

-

The cable armor is visibly damaged or corroded.

-

The insulation shows signs of melting or breakdown.

-

The cable no longer complies with updated electrical codes.

-

There are frequent electrical faults or grounding issues.

Consult with a certified electrician to determine whether partial or full replacement is necessary.

Final Thoughts

Proper usage and regular maintenance of AFC Cable Systems can make a significant difference in both safety and performance. From selecting the right cable type to ensuring long-term care, every step you take contributes to a more efficient and reliable electrical system.

By following the tips and best practices outlined in this guide, you can extend the life of your AFC cable installations, reduce downtime, and maintain code compliance across your operations. Whether you’re managing a large commercial project or working on a home renovation, AFC Cable Systems offer the durability and flexibility you need—just make sure to care for them the right way.

- Maintain and Use Your AFC Cable Systems Efficiently

- Ensure any additions to your AFC Cable Systems (such as junction boxes or extension fittings) are compatible and rated for use with the same type of cable.

- AFC Cable Systems

Related posts:

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

Embracing the Call — Supporting Life Through Christian Faith

Embracing the Call — Supporting Life Through Christian Faith

Make Waves on Your Birthday with SunFunFTL’s Luxury Boat Rentals in Fort Lauderdale

Make Waves on Your Birthday with SunFunFTL’s Luxury Boat Rentals in Fort Lauderdale

Biodegradable Packaging Trends Across Asia-Pacific & Global Markets

Biodegradable Packaging Trends Across Asia-Pacific & Global Markets