When it comes to construction, manufacturing, or engineering projects, choosing the right material is crucial. Among various structural steel options available in the market, the IS 2062 E250A Plate stands out for its versatility, strength, and durability. But how do you ensure you pick the right IS 2062 E250A plate for your specific project requirements? This article will guide you through the essential factors to consider, explaining the material’s properties, composition, and practical applications.

Understanding IS 2062 E250A Plate

Before diving into the selection process, it’s important to understand what IS 2062 E250A really means.

IS 2062 is an Indian Standard specification that defines the requirements for hot-rolled carbon steel plates, sheets, and strips used for structural purposes. It ensures that the steel meets certain mechanical and chemical standards necessary for construction and industrial applications.

The E250A grade within IS 2062 specifies a particular classification of steel with minimum yield strength of 250 MPa, making it suitable for various moderate structural applications.

What Makes IS 2062 E250A Material Special?

The IS 2062 E250A material is widely used due to its excellent balance of strength, ductility, and weldability. It is engineered to provide dependable performance in conditions requiring reliable structural integrity without the need for specialized heat treatments.

Key Features of IS 2062 E250A Material:

- High tensile strength with good elongation properties.

- Excellent weldability, which allows easy joining without compromising strength.

- Reasonable resistance to corrosion, making it suitable for many environments.

- Cost-effective compared to higher-grade structural steels, without sacrificing performance.

Chemical Composition of IS 2062 E250A Plate

The chemical makeup of steel largely dictates its mechanical properties and behavior in different applications. The IS 2062 E250A chemical composition ensures the steel’s strength and workability by maintaining specific limits on elements such as carbon, manganese, sulfur, phosphorus, and others.

| Element | Percentage Range (%) |

|---|---|

| Carbon (C) | 0.20 – 0.25 |

| Manganese (Mn) | 0.30 – 0.90 |

| Sulfur (S) | Max 0.050 |

| Phosphorus (P) | Max 0.050 |

| Silicon (Si) | 0.03 – 0.30 |

This carefully controlled composition allows IS 2062 E250A steel to maintain strength while preventing brittleness, ensuring durability in structural applications.

Factors to Consider When Selecting IS 2062 E250A Plate

Choosing the right steel plate for your project involves more than just knowing the grade or composition. Here are critical factors to keep in mind:

1. Project Requirements & Load Conditions

Understand the mechanical requirements of your project—whether the steel plate needs to bear heavy loads, withstand impact, or offer flexibility. The E250A grade typically suits moderate load-bearing needs, such as in general construction, bridges, and machinery parts.

2. Thickness & Dimensions

IS 2062 E250A plates come in various thicknesses and sizes. The choice depends on the structural design, welding requirements, and the expected stress levels. Thicker plates offer higher strength but may add weight and cost.

3. Environmental Conditions

Consider the environment where the steel will be used. For example, exposure to moisture or chemicals may require steel with additional protective coatings or specific treatments beyond the basic IS 2062 E250A specifications.

4. Welding and Fabrication Needs

If your project involves welding or forming, the IS 2062 E250A material is preferred for its good weldability. However, consider the specific welding methods and whether additional pre- or post-welding treatments are needed.

5. Budget & Availability

Balancing cost with performance is always important. The IS 2062 E250A plate offers an economical solution for many applications, but prices may vary depending on thickness, size, and supplier.

Advantages of Using IS 2062 E250A Plate

Selecting the right IS 2062 E250A plate comes with several benefits:

- Versatility: Suitable for a broad range of structural applications.

- Consistent Quality: Adherence to Indian Standards ensures reliability.

- Ease of Fabrication: Good weldability and machinability reduce construction time and costs.

- Durability: Maintains mechanical properties under various stresses.

Common Applications of IS 2062 E250A Plates

Knowing where this steel grade is commonly applied can help you decide if it’s the right fit for your project:

- Structural frameworks in buildings and bridges.

- Manufacturing of heavy machinery parts.

- Shipbuilding and marine structures.

- Fabrication of tanks and containers.

- Automotive components.

Conclusion

Selecting the right IS 2062 E250A Plate for your project requires understanding its chemical composition, mechanical properties, and the specific demands of your application. This steel grade is an excellent choice for many structural projects due to its balance of strength, weldability, and cost-effectiveness.

- How to Select the Right IS 2062 E250A Plate

- Learn how to choose the right IS 2062 E250A plate with insights on material properties, chemical composition, and application tips

- IS 2062 E250A Steel Plates

Related posts:

Dresses Dry Cleaner services Lisle, IL: BY Napervalue Cleaners

Dresses Dry Cleaner services Lisle, IL: BY Napervalue Cleaners

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

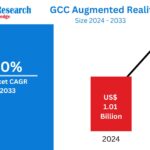

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

Embracing the Call — Supporting Life Through Christian Faith

Embracing the Call — Supporting Life Through Christian Faith

CPT vs ICD-10 Codes: What Every Medical Biller Needs to Know

CPT vs ICD-10 Codes: What Every Medical Biller Needs to Know