Introduction: Redefining Industrial Paradigms

The Industrial Automation Systems Market signifies a fundamental transformation in how modern manufacturing and production enterprises operate. Once dominated by manual labor and electromechanical processes, industrial operations are now undergoing a profound evolution—characterized by intelligent machines, autonomous systems, and data-centric methodologies. The shift from analog to digital workflows reflects a strategic imperative to enhance efficiency, minimize operational errors, and elevate scalability. Industrial automation is no longer optional; it is the nexus of productivity and precision in a hyper-competitive global economy.

For more info visit : https://market.us/report/industrial-automation-systems-market/

Technological Pillars of Industrial Automation

At the core of industrial automation lie an array of advanced technologies converging to optimize factory performance. Robotics systems—particularly collaborative robots (cobots)—have matured to perform intricate tasks with micron-level accuracy, mitigating human error and fatigue. Artificial Intelligence (AI) algorithms augment decision-making processes by enabling predictive maintenance, real-time defect detection, and adaptive learning across the production chain.

Machine vision, coupled with high-speed image processors, enables systems to identify anomalies invisible to the human eye, thereby improving product quality assurance. Equally crucial is the Industrial Internet of Things (IIoT), which weaves a digital thread across the manufacturing floor. Through interconnected sensors, devices, and cloud infrastructure, IIoT facilitates real-time data acquisition, diagnostics, and control—creating a cyber-physical environment where every asset is traceable, and every process is measurable.

Market Drivers and Economic Impulses

Several macroeconomic and microeconomic elements are catalyzing the expansion of the industrial automation systems market. The rising demand for cost-efficiency, production consistency, and minimization of human error are at the forefront. With global supply chains becoming increasingly complex, manufacturers are seeking systems that offer real-time responsiveness and adaptability. Furthermore, the push toward mass customization—where customer-centric products must be delivered at scale—demands the flexibility that only automation can offer.

Government incentives and policy frameworks in regions such as North America, Europe, and East Asia are also reinforcing adoption. Initiatives like “Made in China 2025,” Germany’s “Industrie 4.0,” and India’s “Production Linked Incentive (PLI)” schemes are examples of policy-driven momentum. Additionally, post-pandemic recovery efforts have accelerated the shift toward automation as companies strive to reduce dependency on manual labor and protect against future disruptions.

For more info visit : https://market.us/report/industrial-automation-systems-market/

Segmental Overview of the Automation Landscape

The industrial automation ecosystem is multifaceted, segmented across components, applications, and geographies. By component, the market is categorized into hardware (controllers, sensors, actuators), software (SCADA, HMI, MES), and services (integration, consulting, maintenance). Hardware dominates in terms of revenue contribution, yet software solutions are experiencing exponential growth due to their role in analytics and system orchestration.

From an end-use perspective, automotive manufacturing remains the largest consumer of automation technologies due to its demand for speed, precision, and scale. However, sectors such as pharmaceuticals, food and beverages, oil and gas, and electronics are rapidly catching up. These industries prioritize hygiene, safety, and process uniformity—areas where automation delivers unmatched value.

Geographically, Asia-Pacific commands a significant share of the market, led by rapid industrialization in China, Japan, South Korea, and India. North America and Europe follow closely, with mature infrastructure and a high degree of technological integration. Emerging markets in Latin America and the Middle East are also exhibiting promising trajectories, driven by infrastructural investments and economic diversification agendas.

Challenges and Infrastructural Limitations

Despite its transformative potential, the implementation of industrial automation systems is not devoid of constraints. A primary challenge lies in the high capital expenditure associated with installing and integrating advanced automation solutions. Small and medium-sized enterprises (SMEs), in particular, often lack the financial bandwidth to invest in cutting-edge systems.

Integration with legacy infrastructure is another critical obstacle. Many industrial facilities still operate with outdated machinery and analog processes, creating compatibility gaps that hinder seamless automation deployment. Furthermore, a global shortage of skilled professionals who can design, maintain, and manage these sophisticated systems presents a long-term bottleneck.

Cybersecurity is also emerging as a pressing concern. As automation systems become increasingly connected to external networks, they are vulnerable to data breaches, sabotage, and intellectual property theft. Ensuring data integrity and protecting operational continuity require robust cybersecurity architectures and continuous monitoring.

Future Outlook and Strategic Forecasts

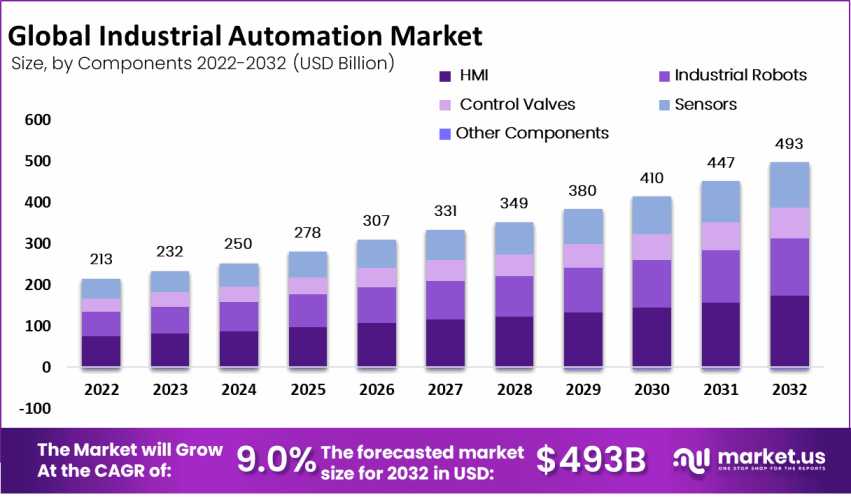

The trajectory of the industrial automation systems market points to sustained growth and innovation. According to current industry estimates, the market is expected to expand at a compound annual growth rate (CAGR) exceeding 8% over the next decade. This growth will be underpinned by next-generation technologies such as edge computing, 5G-enabled industrial connectivity, and autonomous mobile robots.

Emerging concepts like “lights-out manufacturing”—where facilities operate without human intervention—are no longer theoretical. Advances in cognitive automation and swarm robotics promise decentralized, self-optimizing systems capable of responding dynamically to changes in demand, inventory, and production constraints.

Sustainability will also emerge as a pivotal factor. Automation systems are being designed to reduce energy consumption, eliminate material waste, and support circular economy models. Companies that invest in intelligent automation not only secure operational efficiency but also align with environmental, social, and governance (ESG) imperatives.

- Industrial Automation Systems Are Reshaping the Future of Manufacturing

- Industrial Automation Systems Market size is expected around USD 493.0 Billion by 2032 from USD 232.0 Billion in 2023, growing at a CAGR of 9.0%.

- industrialautomation, smartmanufacturing

Related posts:

Why KBH Games Is Perfect for Family-Friendly Online Entertainment

Why KBH Games Is Perfect for Family-Friendly Online Entertainment

Build a Seamless School Portal with These Powerful Templates

Build a Seamless School Portal with These Powerful Templates

7 Ways Aerospace Companies Are Using Composites to Elevate Aerial Robotics

7 Ways Aerospace Companies Are Using Composites to Elevate Aerial Robotics

High-Quality Biomedical Waste Incinerators & Laboratory Glassware Made in India

High-Quality Biomedical Waste Incinerators & Laboratory Glassware Made in India

Understanding the Role of IoT in Modern Manufacturing: A Comprehensive Guide to Smart Factories and Industrial Transformation

Understanding the Role of IoT in Modern Manufacturing: A Comprehensive Guide to Smart Factories and Industrial Transformation

Best Account Management Software for All Businesses – EmizenTech

Best Account Management Software for All Businesses – EmizenTech

Top 15 Global Website Design Companies You Can Hire in the 2025

Top 15 Global Website Design Companies You Can Hire in the 2025

Empowering Qatari Retail Businesses with Microsoft Dynamics 365 Commerce

Empowering Qatari Retail Businesses with Microsoft Dynamics 365 Commerce