Protecting fragile items while preserving presentation and hygiene is critical in the food packaging sector. This is especially true with deli products, including cheeses, cured meats, and pastries, which require precise handling to maintain freshness and beauty. Custom deli paper has become a flexible answer combining branding possibilities with practicality.

To guarantee the best quality, though, handling such delicate materials calls for knowledge, the proper tools, and meticulous attention to detail. This essay explores the subtleties of handling sensitive materials with custom deli paper, stressing why food companies should use it and how it may improve brand identification and product safety.

Special Characteristics

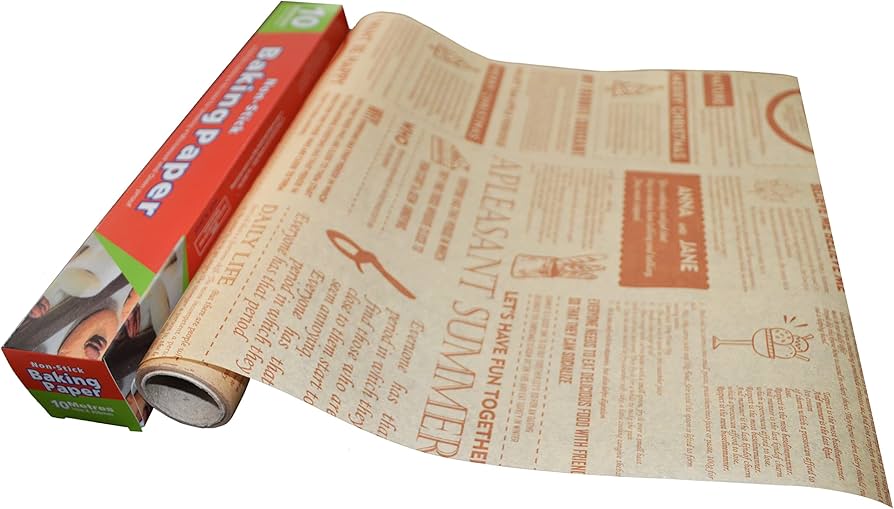

Custom deli paper is especially made for food contact and provides breathability and moisture control to maintain freshness unlike ordinary wrapping sheets. Custom deli paper rolls and custom deli paper sheets allow you to fit varying packaging requirements. Deli paper’s thin, flexible character—often mixed with unique coatings or creative prints—makes it especially sensitive. Careful management of this mix during manufacturing and packaging will help to prevent ripping or breaking the paper, therefore compromising both visual attractiveness and product protection.

Why Managing Sensible Materials Matters?

Handling sensitive items like custom deli paper incorrectly could cause expensive waste, ruined packaging, and eventually unhappy consumers. If improperly handled, thin sheets of deli paper might crease, shred, and print smudge. This not only influences the presentation but also exposes items to top pollutants, compromising food safety. Knowing the fragility of these materials helps companies purchasing custom deli paper wholesale maximize packing processes, therefore lowering losses and improving operational efficiency.

Choosing the Correct Paper for Your Needs

Not every deli paper is produced equally. Custom deli paper selection should take the food type being wrapped, intended shelf life, and branding needs into account. For example, deli paper New Zealand vendors sometimes stress quality criteria that satisfy local food safety requirements. Furthermore, the choice of plain or custom-printed deli paper affects handling techniques since printed papers may need less aggressive processing to avoid ink damage. Matching the correct paper type to your product guarantees that fragile objects remain aesthetically pleasing and safe.

Appropriate Environment and Storage Conditions

Before use, delicate deli paper needs to be kept in ideal conditions to maintain its integrity. Print quality can be compromised and paper fibers weakened by humidity or direct sunshine. Maintaining bespoke deli paper rolls and sheets in a climate-controlled environment lowers the chance of warping or early wear. For food packaging materials, especially, proper storage also helps to avoid contamination from dust or moisture. Companies that make investments in effective storage techniques discover that handling sensitive goods smoothly during packaging comes more easily.

Machines and Equipment Adaptations

Managing delicate custom deli paper for automated packing calls for certain machine settings. Machines have to be tuned to softly feed paper, therefore preventing too strong tension that can lead to tears. Perfect tuning of cutting and folding mechanisms will help to preserve tidy edges and stop damage to printed graphics. Changing or modifying machinery to fit sensitive materials guarantees consistent packaging quality and lowers downtime resulting from paper jams or faults for businesses employing bespoke deli paper wholesale.

Staff Training on Careful Handling

When handling delicate deli paper, even the greatest tools cannot make up for a lack of human attention. Employees engaged in manufacturing and packing should be educated to understand the delicate character of these materials and treat them correctly. Little acts like washing your hands, avoiding too much force, and gently loading paper rolls can drastically cut waste and damage. Well-trained staff help greatly to preserve brand appearance and keep bespoke deli paper sheets in great quality.

Using Custom Printing Without Sacrificing Durability

Custom printing presents great branding possibilities, but when working with delicate deli paper, it adds still another level of complication. Printing inks and techniques have to fit the paper to prevent smearing or breaking. Working with seasoned printers who know how to mix vivid designs with the delicate nature of the paper is essential while obtaining custom-printed deli paper. Through sturdy and aesthetically pleasing packaging produced by this cooperation, consumer impression is improved without compromising functionality.

Environmental Integrity and Sustainability

Many companies looking for sustainable solutions for bespoke deli paper are driven by growing consumer demand for environmentally friendly packaging. Though they might be even more delicate than conventional kinds, biodegradable and recyclable deli papers are available. Careful handling of these items is essential to avoid waste and harm. Finding custom deli paper wholesale suppliers that give sustainability first priority also helps companies match green practices, so appealing to consumers who care about the environment and yet upholding strict packaging standards.

Collaborating with Dependable Vendors

Handling and procuring delicate custom deli paper successfully depends mostly on selecting the correct source. In addition to premium paper, dependable vendors provide professional guidance on appropriate handling procedures, storage options, and compatible printing methods. Working with experienced wholesalers guarantees constant supply, reasonable pricing, and the newest custom sandwich paper wholesale, technological breakthroughs for companies in New Zealand and abroad. This partnership helps to ensure seamless operations and lessen unforeseen problems with delicate packing materials.

In Essence

Managing sensitive materials like custom deli paper calls for a thorough approach, including the appropriate product selection, cautious storage, specialized tools, educated personnel, and strategic alliances. Deli paper is delicate, particularly when custom printed or delivered in rolls and sheets, hence, careful attention to preserve its protective characteristics and aesthetic attractiveness is essential. Food companies that give these elements top priority can cut waste, increase packing efficiency, and strengthen brand image with premium, elegantly presented deli products. Investing in the appropriate handling of custom deli paper finally results in a better market position and satisfied consumers.

- Managing Delicate Materials Using Custom Delicate Deli Paper

- Learn how to properly handle fragile custom deli paper using wholesale alternatives, sheets, and custom deli paper rolls for outstanding packaging.

- custom deli paper, custom deli paper roll, custom deli paper sheets, deli paper newzeland, custom printed deli paper, custom deli paper wholesale

Related posts:

Discover Why Custom Greaseproof Paper Is Changing Food Packaging Forever

Discover Why Custom Greaseproof Paper Is Changing Food Packaging Forever

How Custom Fast Food Boxes Are Making Packaging More Impactful Today

How Custom Fast Food Boxes Are Making Packaging More Impactful Today

Custom CBD Oil Boxes: Why They’re Essential for Building Your Brand

Custom CBD Oil Boxes: Why They’re Essential for Building Your Brand

Boost Your Business with Custom Printed Fish and Chip Paper Today

Boost Your Business with Custom Printed Fish and Chip Paper Today

Discover the Benefits of Custom Heat Seal Paper for Your Business

Discover the Benefits of Custom Heat Seal Paper for Your Business

Maximize Product Perception Using Premium Custom Glassine Paper

Maximize Product Perception Using Premium Custom Glassine Paper

The Challenges Of Food Photography: What Sets Professionals Apart

The Challenges Of Food Photography: What Sets Professionals Apart

Sugarcane Bagasse: The Sustainable Revolution in Eco-Friendly Packaging

Sugarcane Bagasse: The Sustainable Revolution in Eco-Friendly Packaging