In the high-speed world of modern manufacturing, cutting tool inserts serve as the silent workhorses that power machining operations across virtually every industry—from automotive and aerospace to construction and electronics. These tiny, precisely engineered components are responsible for shaping, drilling, turning, and finishing materials with unmatched precision and efficiency.

The global cutting tool inserts market is experiencing robust growth driven by rapid industrialization, technological innovation, and rising demand for high-performance machining solutions. As industries increasingly adopt CNC (Computer Numerical Control) machinery, automation, and smart manufacturing, the need for durable, high-precision inserts is growing exponentially.

Get More Details: https://www.databridgemarketresearch.com/reports/global-cutting-tools-inserts-market

What Are Cutting Tool Inserts?

Cutting tool inserts are replaceable components used in machine tools to perform metal cutting and shaping operations. Unlike traditional tools, which require complete replacement after wear, inserts are designed to be easily swapped out—saving time and cost while improving tool longevity.

Types of Cutting Tool Inserts:

-

Carbide Inserts – Known for toughness, heat resistance, and longevity.

-

Ceramic Inserts – Best suited for high-speed machining of hard materials.

-

CBN (Cubic Boron Nitride) Inserts – Ideal for cutting hardened steels.

-

PCD (Polycrystalline Diamond) Inserts – Used in non-ferrous and abrasive materials.

-

Cermet Inserts – Offer improved wear resistance and finish quality in turning applications.

Market Overview

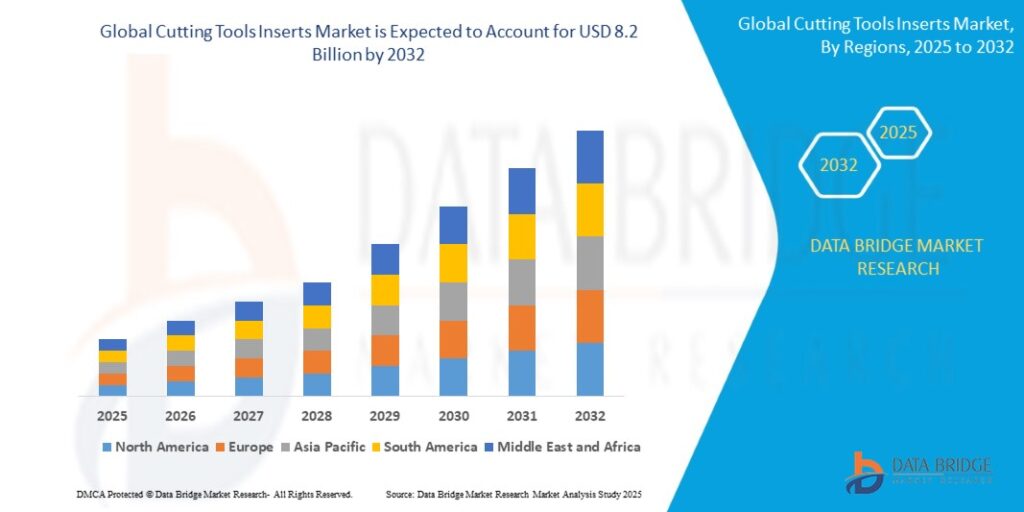

The global cutting tools inserts market size was valued at USD 6.2 billion in 2024 and is projected to reach USD 8.2 billion by 2032, with a CAGR of 3.60% during the forecast period of 2025 to 2032. The surge in demand is largely attributed to:

-

Rising industrial automation

-

Expansion of the automotive and aerospace sectors

-

Increased investment in infrastructure and construction machinery

Key Market Drivers

🏭 Boom in Manufacturing and Automation

With the rise of Industry 4.0, industries are automating their machining operations, requiring advanced cutting inserts that support precision, speed, and repeatability.

🚗 Automotive and Aerospace Expansion

Both sectors demand high-tolerance, high-strength materials like titanium and superalloys, which require premium inserts for efficient machining.

🏗 Construction and Infrastructure Development

Heavy machinery and construction equipment parts are predominantly metal-based, driving consistent demand for milling and turning inserts.

🔬 Advancements in Tooling Materials and Coatings

Inserts today come with nanocoatings, multi-layer surfaces, and heat-resistant properties, extending their lifespan and cutting efficiency.

Challenges in the Market

-

High Raw Material Costs – Elements like tungsten carbide, diamond, and CBN significantly influence insert prices.

-

Wear and Tool Life Issues – Even premium inserts face challenges when exposed to extreme temperatures and abrasive materials.

-

Skilled Labor Shortages – Effective use of high-performance inserts requires trained machinists and advanced CNC operators.

Applications of Cutting Tool Inserts

🔧 Turning Operations

Inserts remove material from rotating workpieces—essential in automotive engine parts and aerospace components.

🛠 Milling Processes

Used for shaping large metal blocks, ideal for mold manufacturing, die casting, and precision engineering.

🔩 Drilling and Boring

Specialized inserts enable high-speed hole-making with superior accuracy and reduced wear.

Regional Insights

-

Asia-Pacific dominates the market, led by China, Japan, and India, where metalworking industries and electronics manufacturing are thriving.

-

North America follows, with strong demand from aerospace, defense, and automotive sectors in the U.S. and Canada.

-

Europe boasts a mature market, with Germany and Italy focusing on precision machining and innovation.

-

Latin America and MEA are emerging regions fueled by infrastructure projects and growing local manufacturing bases.

Future Trends and Innovations

🧠 AI & IoT-Driven Tool Monitoring

Smart tooling systems use sensors and AI algorithms to monitor insert wear and predict replacement needs in real time.

⚙️ Additive + Subtractive Hybrid Machining

As additive manufacturing grows, hybrid machining tools with replaceable inserts are being developed to complement 3D printing.

🌱 Eco-Friendly Insert Manufacturing

Toolmakers are exploring recycled materials and sustainable coatings to reduce the environmental footprint of insert production.

Key Players in the Market

Top companies shaping the market landscape include:

-

Sandvik Coromant

-

Kennametal Inc.

-

Iscar Ltd.

-

Mitsubishi Materials Corporation

-

Sumitomo Electric Industries

-

Walter Tools (A Sandvik Company)

These firms are heavily invested in R&D, nanotechnology, and customer-specific tool solutions to stay ahead in a competitive market.

Conclusion

The Cutting Tool Inserts Market is evolving rapidly, powered by manufacturing excellence, technological advancement, and the need for precise metalworking solutions. As industries shift toward smarter and more efficient operations, the demand for high-performance cutting inserts will only intensify. To thrive in this dynamic market, manufacturers must continue to innovate, invest in automation, and prioritize sustainability.

FAQs

1. What are cutting tool inserts used for?

Cutting tool inserts are used in machining operations like turning, milling, and drilling to shape and cut metal or composite materials in manufacturing.

2. What materials are commonly used in cutting inserts?

Common materials include carbide, ceramic, CBN, PCD, and cermet, each suited for different machining environments.

3. Why are carbide inserts so popular?

Carbide inserts are known for high hardness, excellent wear resistance, and the ability to operate at high cutting speeds.

4. How is technology transforming the cutting tool inserts market?

Technologies like nanocoatings, AI-based monitoring, and hybrid machining are improving tool performance, durability, and predictive maintenance.

5. Which industries use cutting tool inserts the most?

Key industries include automotive, aerospace, construction, energy, and precision manufacturing, all of which rely heavily on metal cutting and shaping.

- Global Cutting Tools Inserts Market Size, Share, and Trends Analysis Report – Industry Overview and Forecast to 2032

- The global cutting tools inserts market size was valued at USD 6.2 billion in 2024 and is projected to reach USD 8.2 billion by 2032, with a CAGR of 3.60% during the forecast period of 2025 to 2032.

- Cutting Tools Inserts Market

Related posts:

Best Website Designer and Web Design Solutions with Cyberworx Technologies

Best Website Designer and Web Design Solutions with Cyberworx Technologies

Plumbing SEO Agency Hacks: Easy Ways to Increase Your Business Earnings

Plumbing SEO Agency Hacks: Easy Ways to Increase Your Business Earnings

Enjoy Ultra 9000 Box of 10 – Power, Flavour, and Convenience Combined

Enjoy Ultra 9000 Box of 10 – Power, Flavour, and Convenience Combined

Crystal Pro Max + 10000 Box of 10: Long-Lasting Flavour from a Trusted Vape Store in UK

Crystal Pro Max + 10000 Box of 10: Long-Lasting Flavour from a Trusted Vape Store in UK

Outrank Competitors with Help from a Trusted Denver SEO Agency

Outrank Competitors with Help from a Trusted Denver SEO Agency

( How SEO Can Be a Game Changer for Your Startup in Australia ) high-speed and competitive startup ecosystem, especially in nations like Australia, business exposure and gaining new customers are no easy feat. With limited funds and minimal resources, startups need strategies that are both effective and cost-efficient

( How SEO Can Be a Game Changer for Your Startup in Australia ) high-speed and competitive startup ecosystem, especially in nations like Australia, business exposure and gaining new customers are no easy feat. With limited funds and minimal resources, startups need strategies that are both effective and cost-efficient

Integrative Neuro Therapy Certification – Certified Training in Functional & Holistic Approaches

Integrative Neuro Therapy Certification – Certified Training in Functional & Holistic Approaches

Everything You Need to Know About Lifeguard Certification Exams

Everything You Need to Know About Lifeguard Certification Exams