In the ever-changing world of industrial automation, user-friendly and reliable HMI software can make all the difference. One of the most trusted solutions used across manufacturing plants today is Aveva InTouch HMI, formerly known as Wonderware InTouch. Known for its powerful visualization tools and ease of use, Wonderware HMI continues to play a critical role in optimizing plant operations, improving safety, and minimizing downtime.

This article explores how manufacturers across various industries are using Wonderware InTouch to boost performance, increase transparency, and maintain tighter control over their systems.

What Is Aveva InTouch HMI?

Aveva InTouch HMI is a Human-Machine Interface (HMI) software used to monitor and control industrial processes. It was originally launched as Wonderware InTouch and has since become part of the Aveva software portfolio.

It enables operators to:

-

Visualize and interact with machinery and processes

-

Monitor key production data in real-time

-

Receive alerts and take timely actions

-

Control systems from a centralized interface

Its popularity stems from being easy to use, scalable, and compatible with a wide range of devices and PLCs.

Why Manufacturers Choose Wonderware InTouch

Choosing the right HMI isn’t just about features. It’s about reliability, efficiency, and the ability to adapt to real-world production needs. Here’s why Wonderware HMI remains a top pick:

-

Proven Track Record: Used in over 100,000 plants globally

-

Quick Configuration: Reduces engineering time by up to 40%

-

Easy Integration: Works well with SCADA, MES, and other industrial systems

-

Built-in Security: Supports role-based access and encrypted communication

Key Applications in Manufacturing

Let’s explore how Wonderware InTouch is used in real-world scenarios across different manufacturing sectors.

Food and Beverage

In this sector, compliance and consistency are key. Aveva InTouch HMI helps track temperatures, batch quality, and recipe execution across automated lines.

Common Use Cases:

-

Real-time monitoring of mixing and filling lines

-

Recipe control with built-in traceability

-

Monitoring clean-in-place (CIP) systems for hygiene standards

Impact:

-

Up to 20% reduction in product waste

-

Faster changeovers between recipes

-

Better compliance with food safety regulations

Pharmaceuticals

Pharma manufacturers face tight controls and documentation requirements. With Wonderware InTouch, they can ensure 21 CFR Part 11 compliance while maintaining efficient production.

Common Use Cases:

-

Batch control with historical tracking

-

Alarm logging and validation reports

-

Integration with electronic batch records (EBR)

Impact:

-

Fewer batch rejections

-

Quicker audits and documentation retrieval

-

Higher equipment utilization

Automotive

Speed, precision, and consistency drive the automotive industry. Wonderware HMI helps ensure consistent quality by giving operators and engineers real-time insight into assembly lines and robotic systems.

Common Use Cases:

-

Robotic cell monitoring and diagnostics

-

Part tracking and error-proofing

-

Energy usage visualization per line or zone

Impact:

-

Up to 15% energy savings

-

Reduction in unplanned downtimes

-

Better traceability of parts

Chemicals and Petrochemicals

Chemical processing involves complex operations that can be hazardous if not handled correctly. Aveva InTouch HMI provides robust monitoring and safety management.

Common Use Cases:

-

Monitoring reactors and tank levels

-

Automated safety interlocks and shutdowns

-

Alarm management and escalation

Impact:

-

Improved operator response time

-

Enhanced plant safety metrics

-

Real-time compliance reporting

Packaging and Logistics

Even after manufacturing, efficiency matters. Wonderware InTouch ensures packaging lines and logistics processes run smoothly.

Common Use Cases:

-

Palletizing robot coordination

-

Barcode verification and sorting

-

Monitoring conveyor belts and sensors

Impact:

-

Reduced shipping errors

-

Increased throughput by up to 18%

-

Better coordination across warehousing teams

Real-World Results from Wonderware InTouch Deployments

Case Study 1: Beverage Manufacturer

A well-known soft drink company used Wonderware InTouch to connect and monitor 12 bottling lines across two facilities. They saw:

-

A 25% drop in downtime

-

$300,000 annual energy cost savings

-

Unified monitoring from a central control room

Case Study 2: Chemical Processing Plant

A mid-size chemical company deployed Aveva InTouch HMI to oversee critical reaction vessels and material feed rates. Results included:

-

Improved safety with predictive maintenance alerts

-

Shortened batch cycle times by 17%

-

Accurate documentation for compliance audits

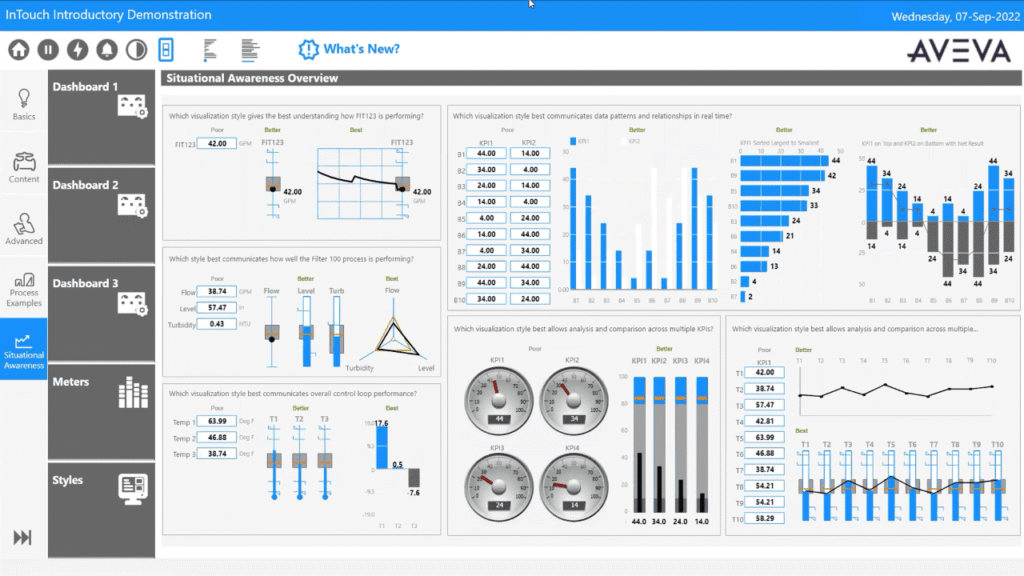

How Aveva InTouch HMI Improves Operator Efficiency

Aveva InTouch HMI is known for its intuitive interface. Operators spend less time training and more time focusing on what matters.

Benefits:

-

Customizable dashboards with real-time KPIs

-

Touchscreen-friendly designs for industrial panels

-

Smart alarms and historical trends for faster diagnostics

Efficiency Boost:

-

30% faster fault response times

-

Easier shift handovers with clear visuals

-

Remote access for supervisors and managers

Future Trends in HMI and What It Means for You

With the rise of Industry 4.0 and IIoT, Wonderware InTouch is evolving too. Manufacturers can now:

-

Access data from mobile devices

-

Integrate AI-based analytics for smarter alerts

-

Use cloud dashboards for global plant monitoring

These improvements make Aveva InTouch HMI not just a display tool, but a real-time decision-making aid.

Why Partner with Pima Controls?

As an authorized system integrator and trusted automation partner, Pima Controls helps manufacturers implement Wonderware InTouch HMI the right way.

What We Offer:

-

Expert HMI consultation and design

-

On-site support and system upgrades

-

Training sessions for operators and engineers

With over three decades of experience, Pima Controls ensures smooth deployment and long-term support tailored to your plant’s needs.

FAQs

What is Wonderware InTouch used for in manufacturing?

It’s used for real-time monitoring, control, and visualization of manufacturing processes, improving efficiency and reducing downtime.

Who can benefit from using Aveva InTouch HMI?

Plant managers, automation engineers, and operators in food, pharma, automotive, and chemical industries can all benefit from using it.

How does Wonderware HMI improve productivity?

It offers better visibility, quicker alerts, and real-time control—helping teams make faster, more informed decisions.

Why is Aveva InTouch HMI better than traditional HMIs?

It’s easier to configure, scales well with plant growth, and integrates with other systems like SCADA and MES without extra coding.

Will Aveva InTouch HMI support remote monitoring?

Yes, with proper setup, it supports remote access via secure networks, enabling monitoring from anywhere.

Where is Wonderware InTouch most commonly used?

It’s widely used in industrial automation, especially in packaging, chemical, food & beverage, and pharmaceutical manufacturing.

Final Thoughts

Aveva InTouch HMI, once known as Wonderware InTouch, continues to prove its value in real-world manufacturing environments. From improving productivity to supporting compliance, its benefits are clear.

If you’re looking to modernize your operations or reduce inefficiencies in your plant, it might be time to consider this trusted solution.

Pima Controls is here to help with every step—planning, implementation, and ongoing support.

- Real-World Uses of Aveva InTouch HMI in Manufacturing

- Explore how Aveva InTouch HMI (Wonderware InTouch) boosts efficiency and control in real-world manufacturing processes with expert insights.

- Aveva InTouch HMI , wonderware intouch ,Wonderware HMI

Related posts:

How UAE Fitout Experts Are Elevating Luxury Brand Spaces in 2025

How UAE Fitout Experts Are Elevating Luxury Brand Spaces in 2025

Sp5der Hoodie: Comfort, Fit, and Real-World Functionality Redefined

Sp5der Hoodie: Comfort, Fit, and Real-World Functionality Redefined

Discover the Best Full Body Massage Experience in Lancaster, PA with Focused Care Therapeutic Massage

Discover the Best Full Body Massage Experience in Lancaster, PA with Focused Care Therapeutic Massage

ISO 27001 Training: A Real-World Lifeline to Reduce the Risk of Data Breaches

ISO 27001 Training: A Real-World Lifeline to Reduce the Risk of Data Breaches

How Instagram Stories Help Businesses: A 2025 gerat Guide ..

How Instagram Stories Help Businesses: A 2025 gerat Guide ..

“GV GALLERY® || TheGv Gallery Shop || Official Clothing Store “

“GV GALLERY® || TheGv Gallery Shop || Official Clothing Store “

Don’t Miss Out on today’s Best Sale Offer with Huge Discounts!

Don’t Miss Out on today’s Best Sale Offer with Huge Discounts!

Why Smart Entrepreneurs Trust a Certified Tax and Business Advisor Over DIY Tax Tools

Why Smart Entrepreneurs Trust a Certified Tax and Business Advisor Over DIY Tax Tools