In today’s quality-driven industries, ensuring the proper application of coatings is crucial for performance, durability, and compliance. Whether it’s a layer of paint, a powder coating, or protective plating, knowing the exact thickness of that coating is essential. This is where the Rimlas Coating Thickness Gauge becomes an invaluable tool. Engineered for accuracy and convenience, it delivers precision on every surface, making it ideal for professionals across a wide range of sectors.

Understanding Coating Thickness Measurement

A coating thickness gauge is a device that measures the thickness of applied coatings on a base material. These coatings may include paint, enamel, galvanization, anodizing, or plating, and the base materials are typically metals. The purpose of measuring coating thickness is to ensure that the coating provides the desired protection and appearance without wasting material or violating industry standards.

Improper coating thickness can lead to problems like corrosion, premature wear, reduced durability, and failed inspections. For this reason, industries ranging from automotive and aerospace to manufacturing and construction rely on coating thickness gauges for quality assurance.

Why Choose Rimlas Coating Thickness Gauge?

The Rimlas Coating Thickness Gauge is designed to meet the growing demand for precision and portability in coating measurement. With its advanced technology, easy-to-use interface, and robust design, it stands out as a reliable instrument for professionals who cannot compromise on quality.

Here’s what sets Rimlas apart:

-

Dual Substrate Measurement: Works flawlessly on both ferrous (steel, iron) and non-ferrous (aluminum, copper) materials.

-

High Accuracy Readings: Delivers micron-level precision, essential for detailed inspections and sensitive applications.

-

Compact & Lightweight Design: Makes it easy to carry and use in the field or lab.

-

Digital Display: Offers real-time, clear readings with minimal user effort.

-

Durable Build: Built to withstand industrial environments and frequent usage.

-

Data Logging Capabilities: Stores multiple readings for batch comparison and report generation.

Key Features at a Glance

-

Measurement Range: Wide measuring range suitable for various industrial needs.

-

Probe Technology: Equipped with advanced probes that ensure repeatable and accurate results.

-

Zero Calibration: Simplifies calibration for quick and precise use.

-

Auto Recognition: Automatically detects the type of base material and adjusts settings.

-

Battery Efficient: Long battery life ensures uninterrupted operation during long inspections.

Industries That Benefit from Rimlas Coating Thickness Gauge

-

Automotive Industry:

-

Used for checking paint thickness on vehicles.

-

Ensures uniform coating on body parts and components.

-

-

Aerospace Industry:

-

Measures protective coatings applied to aircraft components.

-

Ensures materials meet strict aerospace safety standards.

-

-

Metal Fabrication & Manufacturing:

-

Used for inspecting galvanized, powder-coated, and plated parts.

-

Helps maintain consistency and prevent material wastage.

-

-

Construction & Infrastructure:

-

Used for measuring anti-corrosion coatings on bridges, tanks, pipelines, etc.

-

Assures long-term durability and regulatory compliance.

-

-

Marine Industry:

-

Ensures anti-rust coatings are applied correctly to ships, docks, and underwater equipment.

-

-

Paint Shops & Coating Facilities:

-

Helps avoid overcoating or undercoating during production.

-

Benefits of Using Rimlas Gauge

-

Improved Product Quality: Assures that the applied coating meets design and safety requirements.

-

Cost-Effective: Prevents overuse of materials and reduces rework.

-

Compliance Ready: Meets international standards like ISO, ASTM, and others.

-

User Friendly: Simple operation makes it suitable for both professionals and beginners.

-

Time-Saving: Speeds up the inspection process without sacrificing accuracy.

Why Precision Matters

Even a few microns of difference in coating thickness can impact the effectiveness of corrosion resistance, thermal insulation, or electrical conductivity. Precision instruments like the Rimlas Coating Thickness Gauge provide confidence in your quality control process, ensuring every product meets expectations.

Final Thoughts

Whether you’re inspecting cars, aircraft parts, machinery, or structural steel, Rimlas Coating Thickness Gauge ensures Precision for Every Surface. It’s not just a tool—it’s a commitment to quality, consistency, and excellence. Rimlas empowers professionals to deliver products that are not only visually appealing but also durable and compliant.

In a world where standards are high and margins for error are low, choosing Rimlas means choosing reliability. Make it a part of your inspection process today and experience the difference accurate measurement makes.

- Rimlas Coating Thickness Gauge – Precision for Every Surface

- Ensure accurate and reliable coating measurements with the Rimlas Coating Thickness Gauge. Designed for both ferrous and non-ferrous surfaces, it offers high precision, easy operation

- coating thickness gauge

Related posts:

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Essentials Hoodie Design Philosophy: Minimalism Meets Statement

Essentials Hoodie Design Philosophy: Minimalism Meets Statement

Law Notes PDF Download: A Smart Resource for Law Students and Aspirants

Law Notes PDF Download: A Smart Resource for Law Students and Aspirants

A Section 8 Company Registration Process with the ngoexperts

A Section 8 Company Registration Process with the ngoexperts

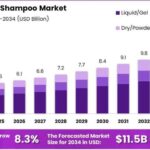

Why the World Is Going Sulfate-Free—One Shampoo Bottle at a Time

Why the World Is Going Sulfate-Free—One Shampoo Bottle at a Time

The mystery to great connections? Acknowledge family and companions for who they truly are

The mystery to great connections? Acknowledge family and companions for who they truly are

Alpaca Apparel Market on the Rise: Sustainability Meets Sophistication

Alpaca Apparel Market on the Rise: Sustainability Meets Sophistication

Warning Signs You May Be Working With An Unqualified Roofing Contractor

Warning Signs You May Be Working With An Unqualified Roofing Contractor