Before vs After: The Fleet Story No One Tells You

Before smart air management, your fleet ran on guesswork. Compressors worked overtime. Fuel was guzzled. Maintenance was reactive, not smart. And delays? They were just part of the job.

Now picture the after: You monitor your compressed air system in real time. You cut the compressor load. You save fuel. You reduce downtime. You manage proactively. Welcome to the future with the master controls air management system.

Why Smart Air Management Pays Off — Big Time

If you’re a CFO, fleet manager, or procurement lead, your priorities are clear: reduce operating costs, minimize risks, and improve ROI. That’s where compressed air — one of the most overlooked energy hogs — comes into focus.

Fact: Compressed air accounts for 30% of industrial energy use, and much of that is wasted due to inefficiencies. (Source: U.S. Department of Energy, Compressed Air Challenge)

Now imagine your compressors using only the air they actually need — not a cubic foot more. That’s what a master controls air management system does.

How Does It Actually Work?

A web-based compressor management system tracks compressor behavior, consumption patterns, and pressure drops. Based on this, it automatically adjusts operations in real time.

Here’s what this means for you:

- Fuel savings of up to 12% per truck per year

- Lower TCO by extending compressor and engine life

- Real-time visibility into compressor health and air consumption

- Predictive maintenance alerts to fix issues before they cost you big

- Fewer breakdowns, fewer surprises, more control

Quick Checklist: Is Your Fleet Leaking Profit?

|

What to Check |

Traditional Setup |

With Smart Air Management |

|

Compressor load frequency |

High |

Adaptive, based on real demand |

|

Maintenance scheduling |

Manual and time-based |

Predictive and optimized |

|

Fuel consumption |

Untracked |

Monitored and reduced |

|

Delay due to air system faults |

Frequent |

Prevented with real-time alerts |

|

Compressor health tracking |

Inconsistent |

Fully automated |

Myth #1: “Our compressors are running fine — we don’t need automation.”

Let’s break this one down. Fine isn’t the same as optimized. If your compressors are running 24/7, how do you know they’re not doing unnecessary work? A master controls air management system learns usage patterns and reduces cycles. That means less wear, less fuel, and longer life — all while doing more.

Real Numbers, Real Impact

Say your fleet has 100 trucks. Each uses 500 gallons of fuel monthly. By reducing compressor load through intelligent automation, you cut just 6% of fuel use per truck.

That’s $3,600 saved per month (at $6/gallon)

Over a year, that’s $43,200 — and that’s just fuel. Now add lower maintenance costs and fewer breakdowns.

And remember: These savings multiply when scaled across regions and routes.

Myth #2: “Smart air systems are too expensive to implement.”

This couldn’t be further from the truth. In fact, smart systems pay for themselves within months. Between fuel savings, fewer service calls, and lower downtime, the ROI is both fast and measurable. With predictive analytics and system insights, you avoid costly surprises and plan better.

Smart Fleets Think Ahead — Do You?

A conventional compressor runs blind. It doesn’t adapt. It doesn’t learn. But an intelligent compressor master controller? It does.

When you rely on data to control air usage, you’re no longer at the mercy of mechanical guessing. You’re in charge — and your compressors work smarter, not harder.

Why Master Controls is the Industry’s Best Choice

With a master controls air management system, you get more than software. You gain:

- Full system transparency from any device

- Custom alerts and reports for your teams

- Scalable solutions fit for fleets of all sizes

- Seamless integration with existing infrastructure

It’s not just about saving costs. It’s about building an intelligent fleet that’s ready for tomorrow’s demands.

Still Thinking About It? Ask Yourself This:

- Can you afford unexpected compressor failures?

- Are you tracking air-related fuel usage today?

- Do you want to make better procurement decisions based on real data?

If the answer is yes to any of these, you need a master controls air management system. The future isn’t coming — it’s already here.

Bottom Line: Smart Air Is Smart Business

Cutting costs starts with control. Real control. And that starts with intelligent air management. Don’t let inefficiency drain your fleet’s potential.

Start small. Think smart. Save big.

- Smart Air Management: The Fleet Cost Saver You Didn’t Know You Needed!

- Before smart air management, your fleet ran on guesswork. Compressors worked overtime. Fuel was guzzled. Maintenance was reactive, not smart. And delays?

- master controls air management system, intelligent compressor master controller

Related posts:

Nutrition and Wellness Programs in Assisted Living Communities in Oakville

Nutrition and Wellness Programs in Assisted Living Communities in Oakville

Dresses Dry Cleaner services Lisle, IL: BY Napervalue Cleaners

Dresses Dry Cleaner services Lisle, IL: BY Napervalue Cleaners

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Welcome to Oasis Fitness: Your Path to Strength, Balance, and Renewal

Welcome to Oasis Fitness: Your Path to Strength, Balance, and Renewal

Essentials Hoodie Design Philosophy: Minimalism Meets Statement

Essentials Hoodie Design Philosophy: Minimalism Meets Statement

Integrating Type form with High Level: A Comprehensive Guide

Integrating Type form with High Level: A Comprehensive Guide

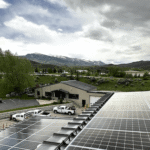

What Solar Looks Like on Flat Roofs, Metal Roofs, and Shingles?

What Solar Looks Like on Flat Roofs, Metal Roofs, and Shingles?

When Best Stock Market Institute Delhi Becomes Your Turning Point Forever

When Best Stock Market Institute Delhi Becomes Your Turning Point Forever