Wearable devices are transforming how we monitor health, stay connected, and enhance performance in daily life. These compact, user-friendly gadgets require advanced electronics that are lightweight, durable, and highly adaptable to different environments. One of the key technological drivers behind this evolution is the development of flex circuit board technology. With each innovation, wearable electronics are becoming more powerful and efficient. This article explores the most important advancements in flex and rigid-flex PCB design and how leading flex circuit board manufacturers are supporting the future of wearable devices with intelligent, high-performance solutions.

Why Flex Circuit Boards Are Ideal for Wearables

Real-World Experience: Performance Meets Comfort

Wearables demand miniaturization and flexibility without compromising function. Traditional rigid boards are limited in this regard, especially for applications worn on the body. From personal use with fitness bands to designing clinical prototypes, it’s clear that flex PCBs offer significant improvements in comfort and adaptability. These boards:

- Bend and fold to fit curved surfaces

- Are lightweight and compact

- Allow for dynamic movement without failure

- Enhance product aesthetics and comfort for the user

This makes them ideal for applications like smart clothing, wristbands, hearing aids, and biometric patches.

- The Rise of Rigid-Flex PCB Integration

Combining Flexibility and Durability

Rigid-flex PCBs integrate the best of both worlds—durable rigid sections with adaptable flexible areas—making them especially useful in complex wearables. These hybrid boards support advanced device features within smaller, more rugged formats.

Partnering with a trusted rigid flex PCB manufacturer ensures access to:

- Efficient design layouts with reduced interconnects

- Enhanced mechanical stability

- Simplified assembly and better space utilization

Blind Buried Circuits offers comprehensive rigid-flex PCB solutions, providing advanced integration tailored to meet the demands of cutting-edge wearable applications.

- Ultra-Thin and Stretchable Flex PCBs

Material Innovation for Ultimate Flexibility

The introduction of ultra-thin and stretchable substrates has revolutionized comfort and performance in wearable electronics. These materials are highly flexible and can conform seamlessly to human skin or fabrics. Applications include:

- Biomedical patches

- Stretchable sensors for sportswear

- On-body computing systems

Benefits include enhanced user comfort, improved adhesion, and better contact for continuous monitoring. This innovation makes wearables less intrusive and more effective, particularly in health and medical contexts.

- Printed Electronics and Conductive Ink Applications

Advancing Cost-Effective, Scalable Solutions

Printed electronics using conductive inks on flexible films represent a major leap toward mass-producing affordable wearable components. These flexible systems can be manufactured using screen or inkjet printing methods.

Common applications include:

- Smart clothing

- Biodegradable health patches

- Flexible touch sensors and NFC devices

This innovation allows for lighter, eco-friendly designs while reducing production costs and lead times. Today’s flex circuit board manufacturers are incorporating these methods into wearable-specific PCB lines, supporting efficient and sustainable innovation.

- Embedded Component Technology

Compact Design, Enhanced Performance

Wearable devices often have limited space for components. Embedded component technology allows resistors, capacitors, and other elements to be built directly into the PCB layers. This provides:

- More compact, low-profile designs

- Greater protection against vibration and environmental stress

- Fewer surface-mounted parts, simplifying assembly

Embedding also supports better signal integrity and reliability, key for devices that transmit biometric or wireless data. Blind Buried Circuits offers advanced embedded solutions specifically suited for wearable technology, helping engineers design smarter, smaller devices.

- High-Density Interconnect (HDI) in Flex Circuits

Supporting Complex Wearables with High-Speed Demands

Wearables such as AR/VR glasses and fitness monitors often require high-speed data processing. HDI technology, with its microvias, laser drilling, and fine-line traces, allows for greater component density in a smaller footprint.

Advantages of HDI flex circuit boards include:

- Increased routing capability

- Enhanced electrical performance

- Reduced signal interference and noise

HDI is becoming essential in the wearables industry, and top-tier flex circuit board manufacturers are using this technology to help clients develop powerful, compact wearable devices.

Cleaning and Maintenance Tips for Wearable Electronics

Drawing from hands-on experience with health wearables, proper cleaning is crucial to maintain performance. Below are a few practical care tips:

- Use a microfiber cloth with isopropyl alcohol for surface cleaning

- Avoid submerging the device in water, even if it’s labeled water-resistant

- Ensure the device is powered off before cleaning

- Allow it to air dry completely to prevent moisture-related damage

These tips help ensure the longevity and safe use of devices built with flex PCBs.

Why Manufacturing Expertise Matters

Choosing the right manufacturer for wearable-specific PCBs is critical. Experience in wearable product design, familiarity with regulatory standards, and precision manufacturing all contribute to the end product’s success.

Blind Buried Circuits has earned recognition for delivering wearable-ready PCBs with rigorous quality control, advanced technologies, and tailored design support. Their dedication to flexible and rigid-flex PCB innovation makes them a reliable partner for companies building next-gen wearables.

Trust, Transparency, and Performance

Working with an expert team builds confidence, especially when launching new wearable products. Transparent communication, material traceability, and custom engineering support contribute to a trusted development process. In our experience, these elements directly impact device success rates, user satisfaction, and time to market.

Whether you’re designing a sports wearable or a medical patch, partnering with a responsive, knowledgeable manufacturer helps you overcome design challenges quickly and efficiently.

Conclusion: Wearable Tech is Just the Beginning

The future of wearable technology lies in smarter, thinner, more comfortable designs and the evolution of PCB technology is what makes it all possible. With contributions from industry-leading flex circuit board manufacturers, innovative substrates, embedded components, and HDI capabilities are reshaping how wearables perform and feel.

As the market continues to grow, choosing a knowledgeable rigid flex PCB manufacturer like Blind Buried Circuits ensures your products are built with the future in mind.

Ready to innovate your next wearable device? Contact Blind Buried Circuits today for high-performance flex and rigid-flex PCB solutions tailored to your vision.

- Top Innovations in Flex Circuit Board Technology for Wearable Devices

- Explore how flex and rigid-flex PCBs are powering the future of wearables with smarter, thinner, and more durable designs from Blind Buried Circuits.

- Circuit Board Technology

Related posts:

Types of Digital Printing Services Available in Dubai dfgrfgt

Types of Digital Printing Services Available in Dubai dfgrfgt

Choosing the Best iPhone 15 Pro Cover for Ultimate Protection

Choosing the Best iPhone 15 Pro Cover for Ultimate Protection

Business Consulting Solutions That Help Scale Your Business Quickly

Business Consulting Solutions That Help Scale Your Business Quickly

The Importance of UX and UI Testing for Exceptional Digital Experiences

The Importance of UX and UI Testing for Exceptional Digital Experiences

Why Bakers Are Switching to Sponge Cake Premix for Consistent Results

Why Bakers Are Switching to Sponge Cake Premix for Consistent Results

Is Your Burlington Home Properly Covered? Understanding Policy Gaps Before It’s Too Late

Is Your Burlington Home Properly Covered? Understanding Policy Gaps Before It’s Too Late

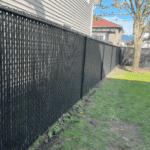

Expert Chain Link Fence Installation Kingston – What You Need to Know

Expert Chain Link Fence Installation Kingston – What You Need to Know

The Rise of the Pull Stussy: A Streetwear Essential pull stussy

The Rise of the Pull Stussy: A Streetwear Essential pull stussy