The plastic mold makers in China remain as leading choices for mold manufacturing, globally. US importers benefit from cost savings, quality work, and scalable production. That being said, finding reliable suppliers in China’s vast market can be difficult. But through this guide, you’ll gain insights on the industry. You’ll learn how to assess manufacturers, control costs, and build strong partnerships for successful sourcing.

Understanding the Plastic Mold Manufacturing Landscape

China’s The dominant position in the World of Manufacturing

China dominates in mold production of plastics, growing steadily each year thanks to strong investments and skilled workers. It serves many industries, offering US importers a broad selection of molds—from simple to complex—at different price points, fitting both new and established businesses.

Key Advantages of Chinese Mold Makers

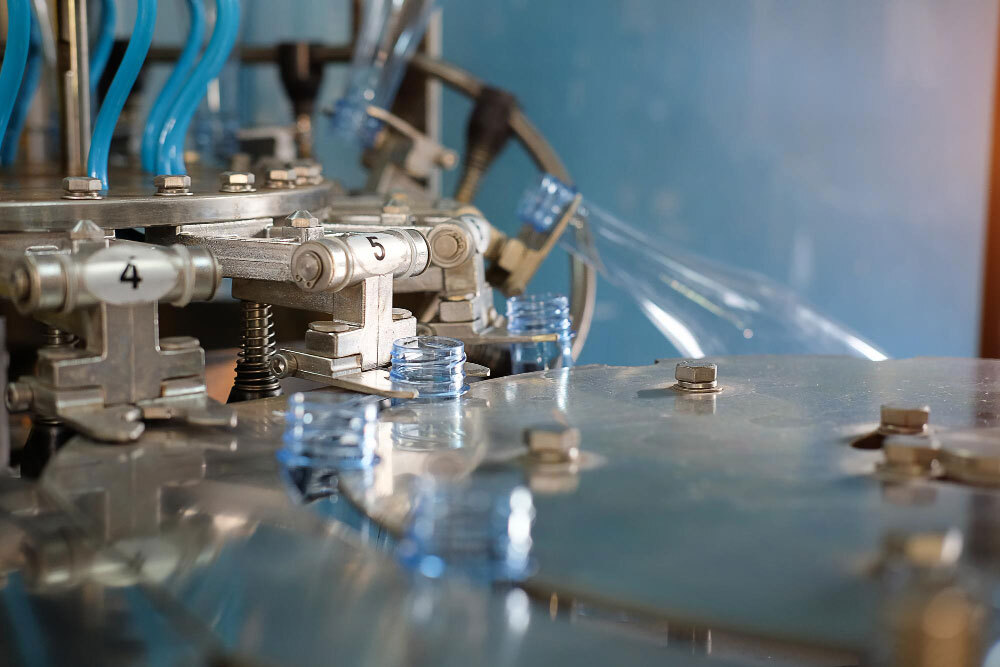

These manufacturers offer affordable pricing thanks to lower labor and material costs. They handle both small prototypes and large orders, adapting to various production needs. Using diverse materials and modern tech like CNC and EDM, they produce precise, high-quality molds that meet different requirements.

Emerging Technologies in Mold Production

The molding industry in China uses advanced tools like CAD/CAM and automation to speed up design and reduce errors. Smart tech such as IoT and data analytics helps monitor molds in real time, predict maintenance, and cut downtime, ensuring high quality and faster delivery.

Choosing the Right Manufacturer

Assessment of Technical Competence and Equipment

Check a company’s skills and tools first. Good suppliers use up-to-date CNC machines and standard parts like HASCO or DME to ensure precision and easy upkeep. Ask about their methods, materials, and quality checks like inspections and test runs to make sure they meet your standards.

Certifications and Quality Standards

Quality is very important when buying molds overseas. Certifications such as ISO 9001 show a factory follows steady processes and aims to improve. Meeting global standards means molds work well and are safe. Always verify certifications and ask for proof. Some fields need special rules, so confirm these when reviewing suppliers.

Protecting Intellectual Property and Ensuring Clear Communication

Protect your designs carefully. Use NDAs, clear contracts, and limit sharing sensitive info. Third-party checks or legal advice add extra safety. Clear communication matters too. Language or cultural gaps can cause delays or errors. Build trust with open channels, bilingual managers, and regular updates.

Controlling Costs and Production Effectiveness

Finding Balance Between Quality and Cost Savings

Cost is often the main reason to source molds from China. However, it is important to balance savings with quality. Extremely low bids may mean corners are being cut. This can lead to defects, rework, or shorter mold life.

What’s more, importers should look for value, not just the lowest price. Consider hidden costs like delays, poor quality, and waste. Spending time early on design reviews and working closely with suppliers can lower costly changes and improve mold quality.

Prototypes to Mass Production

Manufacturers offer flexibility in production volumes. Quick-turn prototyping helps importers test designs and launch products faster. Modular molds let them make improvements without rebuilding the entire tool.

For long-term projects, investing in high-quality, durable molds can reduce maintenance costs and improve consistency across production runs.

Smart Manufacturing and Automation Advantages

Automation technologies in Chinese mold shops help reduce cycle times and improve repeatability. Robotic handling, automated polishing, and CNC machining centers increase efficiency and reduce human error.

On top of that, smart manufacturing practices, including real-time monitoring and data analytics, enable proactive maintenance and quality control. These technologies make mold-making more precise, reliable, and affordable. Importers benefit from faster delivery and better-quality molds.

Creating Powerful and Fruitful Partnerships

Verifying Suppliers and Applying Due Diligence

Before choosing a supplier, thorough checks should be done. Importers should audit factories, inspect samples, and get references. Third-party inspections offer unbiased views of quality and capabilities. Look for partners who respond quickly, are transparent, and solve problems well. Reliable suppliers share issues early and work with you to resolve them.

Maintaining Clear Communication

Regular, open communication helps manage expectations and project success. Use management tools, hold video calls, and employ bilingual staff to overcome language and cultural barriers. Clear records of specs, schedules, and responsibilities prevent misunderstandings and keep work on track.

Fostering Long-Term Collaboration

Long-term partnerships bring benefits like better prices, quicker responses, and stronger support. Many Chinese manufacturers provide services after production, such as maintenance, repairs, and warranties. Strategic collaborations encourage ongoing improvement, innovation, and smoother supply chains.

Trends Shaping the Future of Plastic Mold Sourcing

Innovative technology and Industry Development in China

China’s mold-making industry is evolving rapidly, driven by rising demand in sectors like electric vehicles, medical devices, and consumer electronics. Manufacturers are focusing on producing more precise, specialized molds while adopting greener production methods. This progress reinforces China’s role as a global leader in plastic mold manufacturing.

Breakthrough in IoT and Data Analytics

IoT and data analytics are changing how molds are monitored and maintained. Real-time tracking allows early detection of issues, better maintenance scheduling, and process improvements. As a result, importers enjoy longer mold lifespans, less downtime, and more consistent quality.

China’s Position in International Supply Chains

Despite trade uncertainties, Chinese mold makers remain vital for US importers. Their capacity to provide affordable, high-quality molds at scale supports worldwide product launches and competitiveness. Importers manage risks by diversifying suppliers but continue to rely on China’s manufacturing strengths.

Key Takeaway

US importers can find reliable, affordable plastic mold makers in China by focusing on skills, certifications, and open communication. Protecting designs and building trustworthy partnerships is key. Staying aware of industry trends and using China’s manufacturing strengths helps navigate global sourcing. So remember, with careful planning and good partnerships, the country is a dependable source for precise, cost-effective plastic molds.

- USA Importers’ Guide to Finding Reliable Plastic Mold Makers in China

- US importers can find reliable, affordable plastic mold makers in China by focusing on skills, certifications, and open communication.

- Plastic mold makers in China, Injection molding in China

Related posts:

Scott Tominaga Demystifies Private Equity – A Beginner’s Guide

Scott Tominaga Demystifies Private Equity – A Beginner’s Guide

These 10 Penny Stocks Could Make You Rich in 2025 – Don’t Miss Out!

These 10 Penny Stocks Could Make You Rich in 2025 – Don’t Miss Out!

American Gold Eagles vs. Gold Buffalos: Which Coin is Right for You?

American Gold Eagles vs. Gold Buffalos: Which Coin is Right for You?

The Advantages of CFD Trading on ZFMarkets Explained for Beginners and Seasoned Traders

The Advantages of CFD Trading on ZFMarkets Explained for Beginners and Seasoned Traders

Limited XPLR Merch Just Released Built on loyalty, suspense, and community

Limited XPLR Merch Just Released Built on loyalty, suspense, and community

ELAN SECTOR 49 GURGAON, SOHNA ROAD India Call +91-7765906259

ELAN SECTOR 49 GURGAON, SOHNA ROAD India Call +91-7765906259

Vito’s Way – A Powerful Story in the Making. Help Us Bring It to Life!

Vito’s Way – A Powerful Story in the Making. Help Us Bring It to Life!

Mutual Fund Deals: How to Decode the Smart Money Moves in Indian Markets

Mutual Fund Deals: How to Decode the Smart Money Moves in Indian Markets