In the quick-evolving world of manufacturing, precision and reliability have emerged as non-negotiable, specifically in industries like aerospace and scientific gadgets. These sectors demand additives that meet the highest requirements of high-quality, consistency, and sturdiness. One manufacturing technique that stands proud for turning in such exacting requirements is CNC precision turning. Specifically, CNC precision became additives and Swiss turn elements have grown to be necessary in assembling the rigorous requirements of aerospace and clinical programs.

In this weblog, we’ll explore why CNC precision turned components are critical for these high-stakes industries, the particular blessings they offer, and the way Swiss turn elements suit into the photograph.

Understanding CNC Precision Turned Components

CNC (Computer Numerical Control) precision turning is a producing technique in which uncooked materials, generally metallic rods or bars, are circled at high speeds while cutting equipment precisely removes excess cloth to create complex, complicated shapes with tight tolerances. This method makes use of automatic equipment controlled by using sophisticated laptop programming, making an allowance for repeatability and exactness not possible to acquire with guide machining.

CNC precision grew to become additives manufactured through this system, regarded for their notable accuracy, floor end, and consistency. The ability to create small, complex geometries makes these additives perfect for programs wherein every micron counts.

Why Aerospace and Medical Sectors Demand Precision Turned Components

1. Extreme Performance Requirements

Both aerospace and scientific industries perform in environments wherein component failure is certainly now not an alternative. Aerospace components have to undergo hot temperature versions, intense mechanical stresses, and corrosive environments. Similarly, scientific gadgets ought to carry out perfectly within the human frame or in sterile environments.

CNC precision turned additives meet these needs with the aid of turning in:

- High dimensional accuracy: Components are machined to precise specs, ensuring right suit and characteristic.

- Superior fabric homes: Specialized alloys and biocompatible substances may be exactly machined without compromising structural integrity.

- Consistent pleasant: Automated CNC machining guarantees that every element matches the unique layout exactly, important for protection and performance.

2. Compliance with Regulatory Standards

Both sectors are heavily regulated. Aerospace additives have to comply with certifications which includes AS9100, whilst scientific gadgets must meet FDA regulations and ISO standards like ISO 13485.

CNC precision turning lets in manufacturers to supply components that meet these strict great controls, way to:

- Traceability: CNC machines can log production records, permitting entire traceability from uncooked cloth to finished component.

- Repeatability: CNC programs make sure each batch of parts adheres to the identical excessive standards, important for regulatory compliance.

- Precision inspections: CNC machining integrates well with quality inspection gear, permitting thorough dimensional verification.

3. Complexity and Miniaturization

Aerospace and scientific gadgets an increasing number of rely on miniaturized, complicated components that perform multiple features simultaneously. Examples include:

- Miniature actuators and valve additives in plane systems.

- Small surgical instruments or implantable device parts in the medical field.

Swiss turn elements, produced by way of specialised CNC Swiss-type lathes, are specially suited for such packages due to their capability to gadget very small diameters with tight tolerances and a couple of capabilities in a single operation. This efficiency reduces meeting steps, improving reliability and reducing charges.

The Role of Swiss Turn Parts in Precision Manufacturing

Swiss flip parts originate from Swiss-kind CNC lathes, which differ from conventional lathes by assisting the raw cloth close to the cutting tool with a guide bushing. This design prevents deflection of long, narrow elements throughout machining, enabling the production of tremendously particular additives with complex geometries.

Key Advantages of Swiss Turn Parts:

- Precision on small diameters: Capable of machining components as small as a fraction of a millimeter with severe accuracy.

- Multi-axis machining: Many Swiss CNC machines can perform milling, drilling, and handing over an unmarried setup, permitting complex parts to be completed without more than one furnishings.

- Material versatility: Swiss turning handles an extensive style of substances, such as titanium, chrome steel, and scientific-grade alloys.

- Reduced waste: High precision method, much less material scrap and greater green production.

In aerospace, Swiss turn parts are used for additives like fuel machine fittings, sensor housings, and actuator components wherein precision and reliability are paramount. In the scientific zone, they’re important for producing implantable device components, surgical equipment, and diagnostic equipment components.

Benefits of CNC Precision Turned Components in Aerospace

Enhanced Safety and Reliability

In aerospace, each element is essential to flight safety. CNC precision became additives to sure reliability with the aid of meeting precise specifications and lowering the chance of manufacturing defects. The high degree of repeatability reduces variability, which means that each element plays as predicted.

Weight Reduction for Fuel Efficiency

CNC turning can create lightweight but robust additives through machining complicated geometries that limit cloth without compromising electricity. This contributes to typical plane weight loss, directly improving fuel performance and lowering emissions.

Cost Efficiency through Automation

Although aerospace additives require tight tolerances and complicated designs, CNC precision turning permits efficient batch production with minimum guide intervention, lowering production fees and lead instances.

Benefits of CNC Precision Turned Components in Medical Applications

Biocompatibility and Sterility

Medical components ought to frequently be made from biocompatible substances including titanium or scientific-grade stainless steel. CNC precision turning allows precise machining of those substances to preserve their integrity and ensure easy finishes, which might be crucial to save you tissue infection or bacterial buildup.

Customization and Complexity

Medical devices frequently require customized elements tailored to affected person-unique needs. CNC precision turning supports fast prototyping and small-batch manufacturing, making it ideal for generating bespoke surgical devices or implants.

Improved Patient Outcomes

The precision and high-quality of CNC machined additives contribute immediately to the effectiveness and protection of medical gadgets, leading to better patient consequences and reduced hazard of complications.

Conclusion: CNC Precision Turned Components as the Backbone of Aerospace and Medical Innovation

In each aerospace and scientific sectors, precision, reliability, and compliance are paramount. CNC precision became components and Swiss flip components provide the solution by handing over consistently great, complex elements that resist worrying operational environments.

Their potential to handle miniaturization, complex geometries, and specialised materials makes them crucial in developing the next technology of aircraft structures and scientific devices. As technology advances and industries push the bounds of overall performance and safety, the position of CNC precision as additives will simplest grow more vital.

For producers and engineers, investing in advanced CNC precision turning abilities and leveraging Swiss turn parts technology method staying in advance in these competitive, high-stakes markets.

If you want to explore CNC precision turned additives or Swiss turn parts on your aerospace or scientific initiatives, connecting with an experienced precision production associate is step one towards making sure excellent, compliance, and innovation.

- Why CNC Precision Turned Components Are Essential in Aerospace and Medical Sectors

- In this weblog, we’ll explore why CNC precision turned components are critical for these high-stakes industries, the particular blessings they offer, and the way Swiss turn elements suit into the photograph.

- Swiss turn parts, CNC precision turned components

Related posts:

Top Carrier Oil Suppliers in India for Bulk & Wholesale Buyers

Top Carrier Oil Suppliers in India for Bulk & Wholesale Buyers

Atlas Pro ONTV : La Révolution de la Télévision par Internet

Atlas Pro ONTV : La Révolution de la Télévision par Internet

Luxury or Budget? Finding the Right Heathrow Transfer for You

Luxury or Budget? Finding the Right Heathrow Transfer for You

What Is Cold Rolled Stainless Steel Coil and Why Does It Matter?

What Is Cold Rolled Stainless Steel Coil and Why Does It Matter?

Make Your Message Stick: The Power of Flyers & Posters in Plano!

Make Your Message Stick: The Power of Flyers & Posters in Plano!

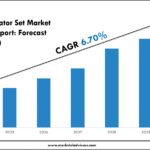

Chile Generator Set Market Trends & Forecast: Outlook to 2030

Chile Generator Set Market Trends & Forecast: Outlook to 2030

Trusted Fiber Laser Cutting Machine Supplier Delivering Advanced Automatic Laser Cutting Machines

Trusted Fiber Laser Cutting Machine Supplier Delivering Advanced Automatic Laser Cutting Machines

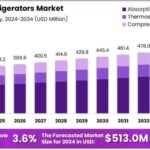

Small-Space Cooling: The Rise of the Minibar Fridge in Minibar Refrigeration

Small-Space Cooling: The Rise of the Minibar Fridge in Minibar Refrigeration