Are you exploring the best way to produce high-quality, full-color apparel quickly, flexibly, and cost-efficiently? The decision can be overwhelming with so many methods available in the print industry today. Custom heat transfers are one solution gaining remarkable momentum across creative, retail, and corporate sectors. Whether you’re a brand looking to launch a limited-edition drop or a team seeking vibrant, durable apparel, custom heat transfers are leading the way in 2025.

This blog dives into what makes this method so effective, how it works, and why it has become a preferred choice for small-scale creators and large-scale distributors. From production flexibility to design fidelity, you’ll gain a complete understanding of how custom heat transfers can elevate your apparel line or promotional campaign.

Soft Finish with Professional Durability

A key advantage of custom heat transfers is the finish they produce on garments. The film conforms smoothly to the fabric, creating a soft, flexible, and long-lasting impression. The print feels natural and remains consistent after repeated washing, whether applied to cotton, polyester blends, or mixed materials. This makes custom heat transfers ideal for apparel that endures frequent wear and laundering, such as uniforms, merchandise, or sportswear.

No Minimum Order Requirement

One of the most attractive features of custom heat transfers is the freedom to order without a minimum quantity. Depending on their project needs, creators and businesses can order a single piece or scale to hundreds. This flexibility encourages design experimentation and allows small batches to be produced without added cost or complexity. Custom heat transfers make it feasible to efficiently meet small and large production goals.

Production Timelines That Fit Modern Schedules

Timing plays a critical role in product launches and promotional events. Custom heat transfers offer a practical production schedule, with standard turnaround averaging ten business days. Once artwork is submitted and approved, the process flows seamlessly into printing and shipping. This reliability allows planners to confidently coordinate deliveries, ensuring the apparel is ready for campaigns, sales, or events.

Designed for Quality and Comfort

The garments selected for custom heat transfers are built with both appearance and feel in mind. Shirts are made from high-quality ring-spun combed cotton and soft poly blends, offering a balance of softness and durability. Features like side seams, shoulder taping, enzyme washing, and tear-away labels enhance fit and finish. With sizes ranging from small to 2XL and various color options including heathers, there is flexibility to suit a broad audience and various branding needs.

Artwork That Prints Perfectly

Artwork must be adequately prepared to get the best results from custom heat transfers. The process supports full-color prints, including gradients and intricate details. Files should be submitted in CMYK format with clear outlines and appropriate resolution. Accepted file types include PDF, PNG, and PSD. The artwork is printed as submitted, giving you complete control over the final result. Additional support or adjustments can be requested during the order process if assistance is needed.

Reorders Made Simple

Once a design has been printed, future orders are quick and straightforward. Customers can reorder using their original order number, ensuring consistency across multiple production runs. This is particularly valuable for businesses, schools, or organizations that need a dependable and repeatable apparel supply. Custom heat transfers provide a streamlined path from first print to long-term brand consistency.

Suitable for All Fabric Colors and Styles

Custom heat transfers’ versatility across various fabric colors and styles is a standout benefit. The printing process applies a white underbase layer, allowing vibrant colors to appear as clearly on dark fabrics as on light ones. This capability is essential for fashion designers and marketers aiming for accurate color representation, regardless of the material’s background shade or texture.

Easy Application and Maintenance

Once the garment is printed and delivered, care and handling are simple. The transferred designs resist cracking or peeling when proper washing guidelines are followed. These include cold water washing, turning garments inside out, tumble drying on low, and avoiding direct heat on the printed area. These easy-to-follow care instructions help preserve the design’s appearance and integrity over time.

A Scalable Solution for Creative Growth

Custom heat transfers are not just a short-term solution but a long-term strategy for brand expansion. The ease of ordering, high production quality, and flexible volume options allow creators to grow at their own pace. Whether launching a seasonal collection, creating promotional items, or outfitting a team, this method supports the full range of apparel needs.

Conclusion

In the landscape of apparel customization, custom heat transfers have established themselves as a reliable, scalable, and professional-grade solution. Their ability to produce vivid, full-color graphics on various fabrics with minimal setup and no order minimums makes them exceptionally appealing. With high-quality materials, straightforward artwork requirements, and a dependable production schedule, this method meets the creative and operational needs of today’s entrepreneurs, businesses, and content creators.

Choosing custom heat transfers means investing in a process that supports one-time projects and ongoing production with consistent results. Its control over design, cost, and scale provides unmatched flexibility. Whether starting with one shirt or preparing a run of hundreds, this approach enables you to maintain brand identity, meet deadlines, and confidently deliver premium-quality apparel.

- What Makes Custom Heat Transfers a Top Choice in 2025

- Shirts are made from high-quality ring-spun combed cotton and soft poly blends, offering a balance of softness and durability.

- custom heat transfers

Related posts:

Nutrition and Wellness Programs in Assisted Living Communities in Oakville

Nutrition and Wellness Programs in Assisted Living Communities in Oakville

Dresses Dry Cleaner services Lisle, IL: BY Napervalue Cleaners

Dresses Dry Cleaner services Lisle, IL: BY Napervalue Cleaners

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Easy EMI Card: Your Go-To Solution for Easy Monthly Payments

Welcome to Oasis Fitness: Your Path to Strength, Balance, and Renewal

Welcome to Oasis Fitness: Your Path to Strength, Balance, and Renewal

Essentials Hoodie Design Philosophy: Minimalism Meets Statement

Essentials Hoodie Design Philosophy: Minimalism Meets Statement

Integrating Type form with High Level: A Comprehensive Guide

Integrating Type form with High Level: A Comprehensive Guide

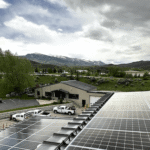

What Solar Looks Like on Flat Roofs, Metal Roofs, and Shingles?

What Solar Looks Like on Flat Roofs, Metal Roofs, and Shingles?

When Best Stock Market Institute Delhi Becomes Your Turning Point Forever

When Best Stock Market Institute Delhi Becomes Your Turning Point Forever