When it comes to strength, durability, and corrosion resistance, stainless seamless steel pipe consistently stands out. Whether you’re working in construction, petrochemical processing, or marine industries, choosing the right pipe can make or break your project. So why should stainless seamless steel pipe be your go-to choice? Let’s explore this versatile product, its applications, and why Jianglin Steel leads the way in custom manufacturing.

What is a Stainless Seamless Steel Pipe?

At its core, a stainless seamless steel pipe is a tubular product made without any welding seams. Unlike welded pipes, these are produced through an extrusion or piercing process, creating a continuous and uniform structure. The result? Higher strength, improved pressure resistance, and a smoother internal finish.

Key Characteristics:

-

No weld seams

-

Uniform strength distribution

-

High resistance to corrosion and oxidation

-

Excellent performance under high pressure and temperature

How Are Stainless Seamless Steel Pipes Made?

Understanding the manufacturing process helps clarify why these pipes are superior in performance. At Jianglin Steel, we follow a precise and high-quality production process:

Step-by-Step Manufacturing

-

Raw Material Selection

We start with premium stainless steel billets. Our sourcing ensures the material meets international standards. -

Heating and Piercing

The billet gets heated and pierced to form a hollow tube using rotary piercers. This critical step eliminates the need for welding, ensuring structural integrity. -

Elongation and Sizing

After piercing, the pipe undergoes elongation, stretching it to the desired diameter and wall thickness. -

Heat Treatment

Pipes are annealed to relieve internal stress and improve ductility and corrosion resistance. -

Finishing

We then cut, straighten, and polish the pipes, ensuring they meet precise tolerances and cosmetic requirements. -

Inspection

Every stainless seamless steel pipe undergoes rigorous testing, including ultrasonic inspection, hydraulic testing, and dimensional checks.

This meticulous process allows us to offer a seamless product that’s not just aesthetically clean but functionally superior.

Why Choose Stainless Seamless Steel Pipe?

1. Superior Corrosion Resistance

In industries like chemical processing and offshore drilling, corrosion is a constant threat. Thanks to its chromium content, stainless steel forms a passive oxide layer that resists rust and corrosion. And because seamless pipes have no welds, there’s no weak point for corrosion to start.

2. Strength and Pressure Resistance

Seamless pipes withstand higher pressures compared to welded alternatives. This makes them ideal for high-pressure applications such as hydraulic systems, oil and gas pipelines, and nuclear power plants.

3. Longevity and Durability

Stainless seamless steel pipes last significantly longer than welded pipes. Since there are no joints or seams, there’s less risk of failure under stress or temperature fluctuations.

4. Smooth Internal Surface

The smooth interior of seamless pipes improves flow efficiency, reduces pressure loss, and prevents contamination—an important factor in food, pharmaceutical, and chemical industries.

5. Low Maintenance

Thanks to their corrosion resistance and smooth finish, seamless pipes require less maintenance. This translates to lower operating costs over time.

Applications of Stainless Seamless Steel Pipes

Stainless seamless steel pipes aren’t limited to one industry. Their versatility makes them suitable across a wide range of sectors.

Industrial Applications

-

Oil and Gas: Used in upstream, midstream, and downstream processes for their strength and corrosion resistance.

-

Chemical Plants: Resistant to aggressive chemicals and high-temperature operations.

-

Food & Beverage: Ensures hygiene due to the clean, smooth inner surface.

-

Pharmaceuticals: Critical for sterile processing lines.

-

Automotive: Used in exhaust systems, fuel lines, and structural components.

Construction & Architecture

-

Building frameworks and structural supports

-

Decorative applications such as railings and handrails

-

Infrastructure like bridges and tunnels

Marine Applications

-

Ships, docks, and offshore rigs face a constant battle with saltwater corrosion. Stainless seamless steel pipes are the first line of defense in these environments.

Welded vs. Seamless: Which is Better?

While both have their place, understanding the difference helps you make an informed choice.

| Feature | Seamless Steel Pipe | Welded Steel Pipe |

|---|---|---|

| Strength | Higher due to no weak seams | Lower due to welding seam |

| Pressure Resistance | Excellent | Moderate |

| Corrosion Resistance | Higher | Depends on weld quality |

| Cost | Higher | Lower |

| Surface Finish | Smooth interior and exterior | Potential internal irregularities |

So, when your project demands uncompromising strength and performance, seamless pipes are the clear winner.

Why Jianglin Steel is Your Best Choice

As a custom stainless steel manufacturer in China, Jianglin Steel brings decades of expertise and advanced manufacturing capabilities to every order. Here’s why our clients trust us:

1. Customized Solutions

No two projects are the same. We work closely with clients to deliver stainless seamless steel pipes in customized sizes, grades, and finishes.

2. Quality Assurance

Our strict quality control ensures every pipe meets international standards such as ASTM, DIN, and JIS.

3. Competitive Pricing

Thanks to our streamlined production and sourcing networks, we provide top-tier quality at highly competitive prices.

4. Reliable Delivery

We understand that time is critical. Our logistics and production teams ensure timely delivery for domestic and international orders.

5. Technical Support

Our engineers and support staff are always available to assist you with material selection, specifications, and technical queries.

How to Order from Jianglin Steel

Ordering is simple and straightforward. Here’s how it works:

-

Contact Us with Your Requirements

Send us your specifications including dimensions, grades, quantity, and delivery time. -

Receive a Custom Quote

We provide a detailed quotation along with lead time and shipping options. -

Approval and Production

Once approved, we begin manufacturing your custom stainless seamless steel pipes. -

Inspection and Delivery

We perform final inspections before securely packing and shipping your order.

Final Thoughts

When you’re building infrastructure, processing chemicals, or outfitting marine equipment, you can’t afford to compromise on quality. Stainless seamless steel pipe offers the reliability, durability, and performance that demanding applications require. At Jianglin Steel, we don’t just manufacture; we partner with you to deliver tailored solutions that meet your exact needs.

If you’re ready to experience the benefits of stainless seamless steel pipes for your next project, contact Jianglin Steel today. Let’s build something stronger—together.

- Why Should You Choose Stainless Seamless Steel Pipe for Your Next Project?

- Explore the benefits, applications, and manufacturing process of stainless seamless steel pipes. Learn why Jianglin Steel is the trusted name in custom stainless steel solutions.

- stainless seamless steel pipe

Related posts:

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

Syna World Redefining Modern Fashion & Syna Worldwide More Than a Brand

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

How the AED to PKR Open Market Rate Affects Pakistani Expats in UAE

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

Top Temperature Data Logger Manufacturers in India – Reliable & Accurate Solutions Powered by Nimbus Technologies

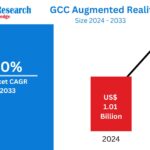

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

GCC Augmented Reality Market Size, Forecast 2025-2033: A Comprehensive Industry Analysis

Embracing the Call — Supporting Life Through Christian Faith

Embracing the Call — Supporting Life Through Christian Faith

Make Waves on Your Birthday with SunFunFTL’s Luxury Boat Rentals in Fort Lauderdale

Make Waves on Your Birthday with SunFunFTL’s Luxury Boat Rentals in Fort Lauderdale

Biodegradable Packaging Trends Across Asia-Pacific & Global Markets

Biodegradable Packaging Trends Across Asia-Pacific & Global Markets

How to Use Magazine WordPress Themes to Create a Unique News Experience

How to Use Magazine WordPress Themes to Create a Unique News Experience